Welcome to the fantastic world of cutting ABS plastic! If you’ve ever wondered about the best ways to cut ABS plastic. You’ve hit the jackpot if you also want to make your projects easy and fun. This introduction is like the beginning of a thrilling adventure. In this guide, we’ll explore fantastic techniques and invent excellent tools. Also, we will pick up some handy tips to cut ABS plastic like a pro. It doesn’t matter if you’re starting out or already a crafting expert. We’ve got helpful insights for everyone. So buckle up and get ready for a journey. And we’ll uncover the secrets to cutting ABS plastic with precision and creativity. Let’s dive in and make your ABS plastic projects successful!

What is ABS plastic?

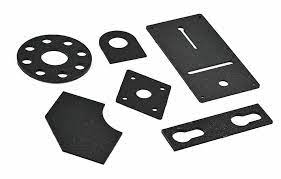

ABS plastic is like a superhero material because it’s super strong and can do a lot of cool stuff! Picture it like a superhero among plastics. Because it combines three unique ingredients. the ingredients are acrylonitrile, butadiene, and styrene – to create a powerhouse combo. This magical mix results in a plastic that’s not only super strong but also durable. It is also as tough as nails, making it resistant to impacts and able to handle heat like a champ. ABS plastic is everywhere, from household items to cool toys and car parts. What makes ABS even more remarkable is that it’s easy to shape into all sorts of forms and is pretty. So, next time you’re using a sturdy toy or grabbing something made of plastic, there’s a good chance it’s the superhero ABS plastic doing its job!

What is the best way to cut ABS plastic?

The most effective method for cutting ABS plastic depends on the specific project and the available tools. Here are some commonly used approaches:

Handsaw or hacksaw:

A fine-toothed handsaw or hacksaw can be employed for cutting ABS plastic. Securing the plastic and executing slow, steady cuts is essential to preventing chipping.

Circular Saw:

A circular saw with a fine-toothed blade proves efficient when dealing with straight cuts or larger projects. Adhering to proper safety measures and using a guide for straight lines is crucial.

Jigsaw:

When cutting hard or curving ABS plastic, a jigsaw using a fine-toothed blade performs well. Taking time and following the desired cutting path is essential for precision.

Utility Knife or Rotary Tool:

A utility knife with a sharp blade or a rotary tool. And a cutting wheel is versatile for various applications, especially for minor, precise cuts. This method is suitable for thinner ABS sheets.

Table Saw:

If a table saw is available, it becomes a powerful tool for cutting large ABS sheets. Adhering to safety guidelines and using proper support for the material is imperative.

What is the best place to learn more about ABS plastic?

There are many ways to learn more about this. You can learn both online and offline. But in these ways, you have to face many odds. So we have a proper solution for you: the Junying website. By visiting Junying’s website, you can learn the proper things you want to know. Besides that, this website is very user-friendly. Visiting this website is like visiting your own house. So be on time to prepare to begin the journey with this friendly site.

FAQs

Why is testing the cutting tool on a scrap piece of ABS plastic recommended?

Testing ensures that the chosen tool yields the desired results, helping avoid errors and ensuring a successful cut on the actual project.

How can I secure ABS plastic during cutting for better results?

Securing ABS plastic prevents unnecessary movement, resulting in cleaner and more accurate cuts while reducing the risk of accidents. Utilize clamps or a stable work surface for improved outcomes.

How do I ensure a straight cut when using a handsaw?

Secure the ABS plastic, and use a straight edge or guide to follow the cutting line. And make slow, steady cuts to achieve a straight and precise result.

Can a utility knife be used for cutting thinner ABS sheets?

A utility knife with a sharp blade or a rotary tool with a cutting wheel suits more minor, more precise cuts, especially on thinner ABS sheets.

Conclusion

Ultimately, your project and the tools at hand will decide the most effective way to reduce ABS plastic. Handsaws, hacksaws, circular saws, jigsaws, pocket knives, rotary instruments, and table-top saws are the tools you can use. It’s like selecting the correct tool for the job, as every tool has qualities! Firstly, try the device on a used piece of plastic, secure it in place, and follow security rules. There is a tool that is perfect for any job, whether making simple lines or detailed turns. So have fun with ABS plastic and making things!