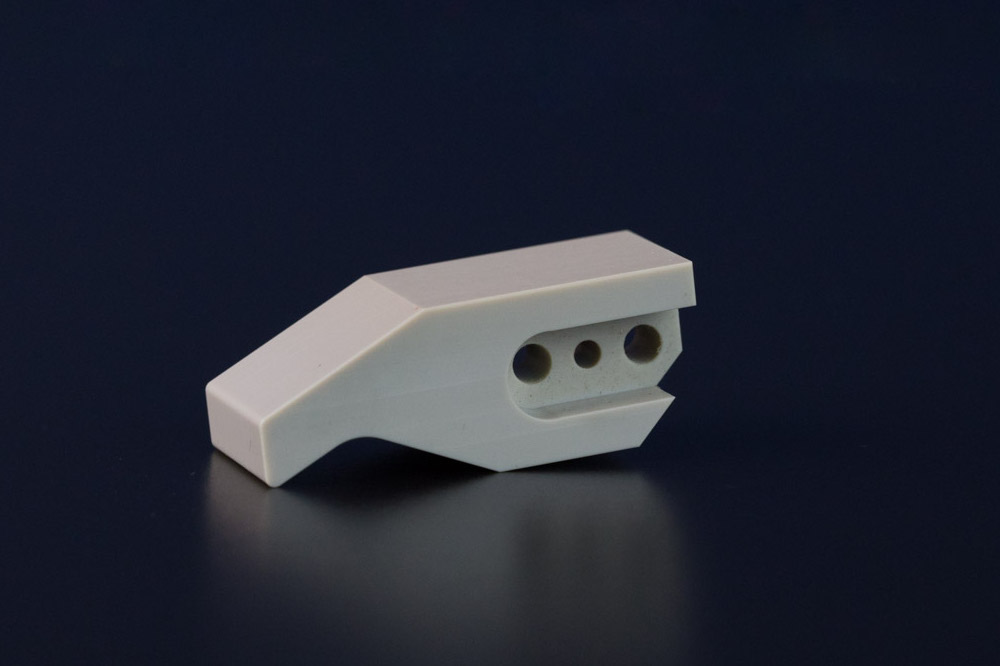

Torlon PAI (Polyamide-imide) 4301 is a wear-resistant grade of PAI that contains amounts of graphite and PTFE. Torlon PAI has a low coefficient of friction, which makes it well-suited to applications related to seals, valve seats, and bearings. In addition, Torlon PAI is a high strength material with great dimensional stability.

- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us