CNC Machining Service

- Instant Quotes & DFM Feedback

- Parts as Fast as 2 days

- Tight Tolerances

- Hand Metrology, Laser & CMM Inspections

Faster Lead Times

With instant online quotes and rapid production, you can reduce cycle times by as much as 50%.

World-Class Machine Shops

Tap into a highly vetted and managed network of the best machine shops world-wide.

Flexible Pricing

Choose between fast and cost-effective options to find the best price.

CNC Machining Services

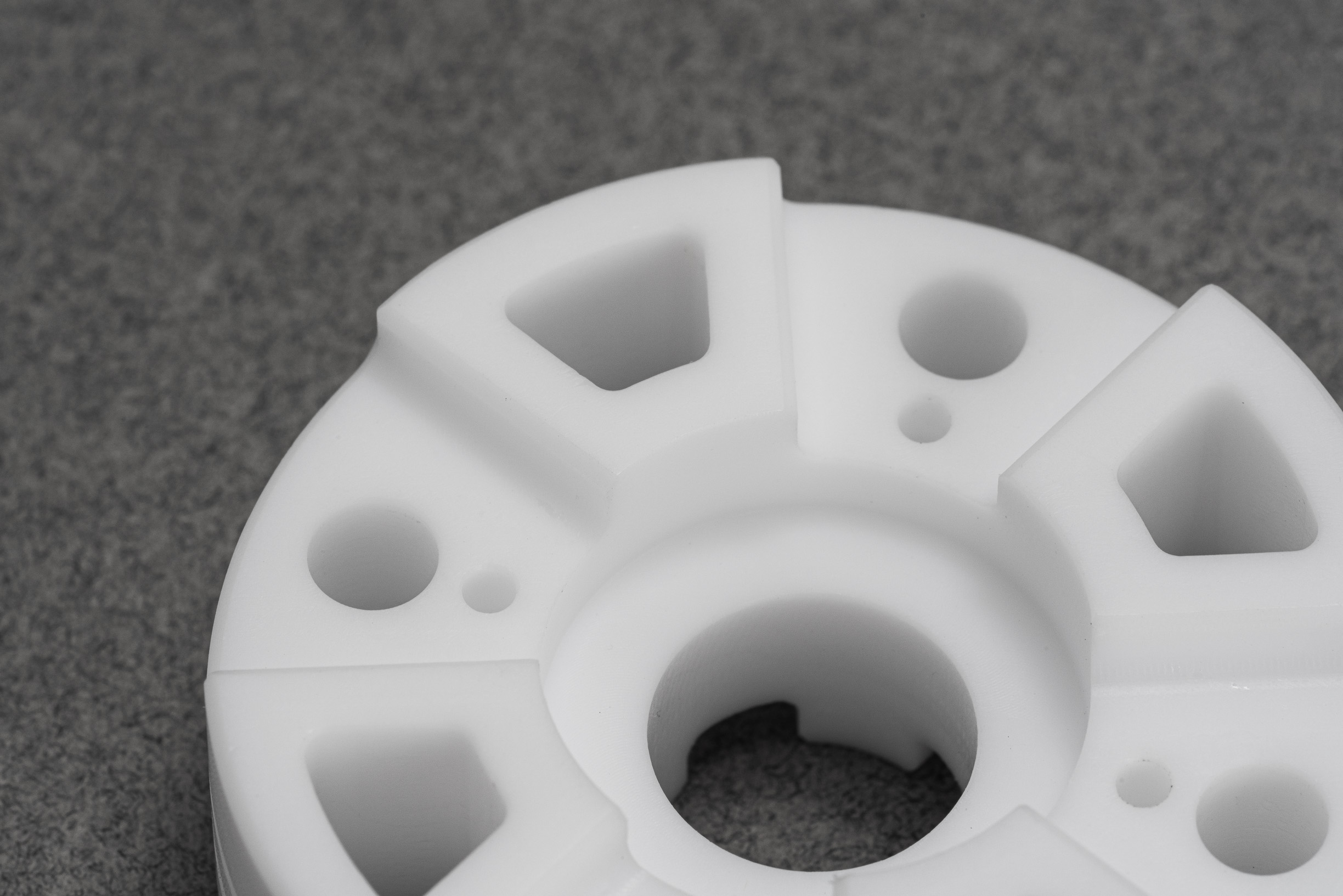

Standard and live tooling capabilities for cylindrical parts such as pins, shafts, and spacers.

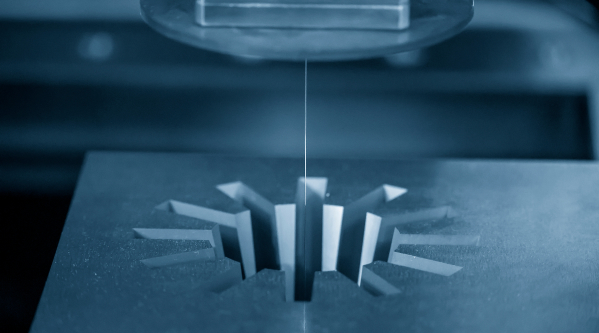

Useful for cutting deep pockets and complex features such as gears and holes with a keyway.

CNC Machining Materials

Excellent hardness and wear resistance are provided by A2 Tool Steel. This material is frequently used to create fixtures, tools, tool holders, gauges, and punches due to its excellent compressive strength and dimensional stability.

Tool steel has a glossy sheen and is slightly darker than aluminum alloys, similar to other mild steel grades. After machining, black oxide can be used to increase corrosion resistance. Tool steel pieces can also be media blasted or tumbled to produce a range of surface finishes.

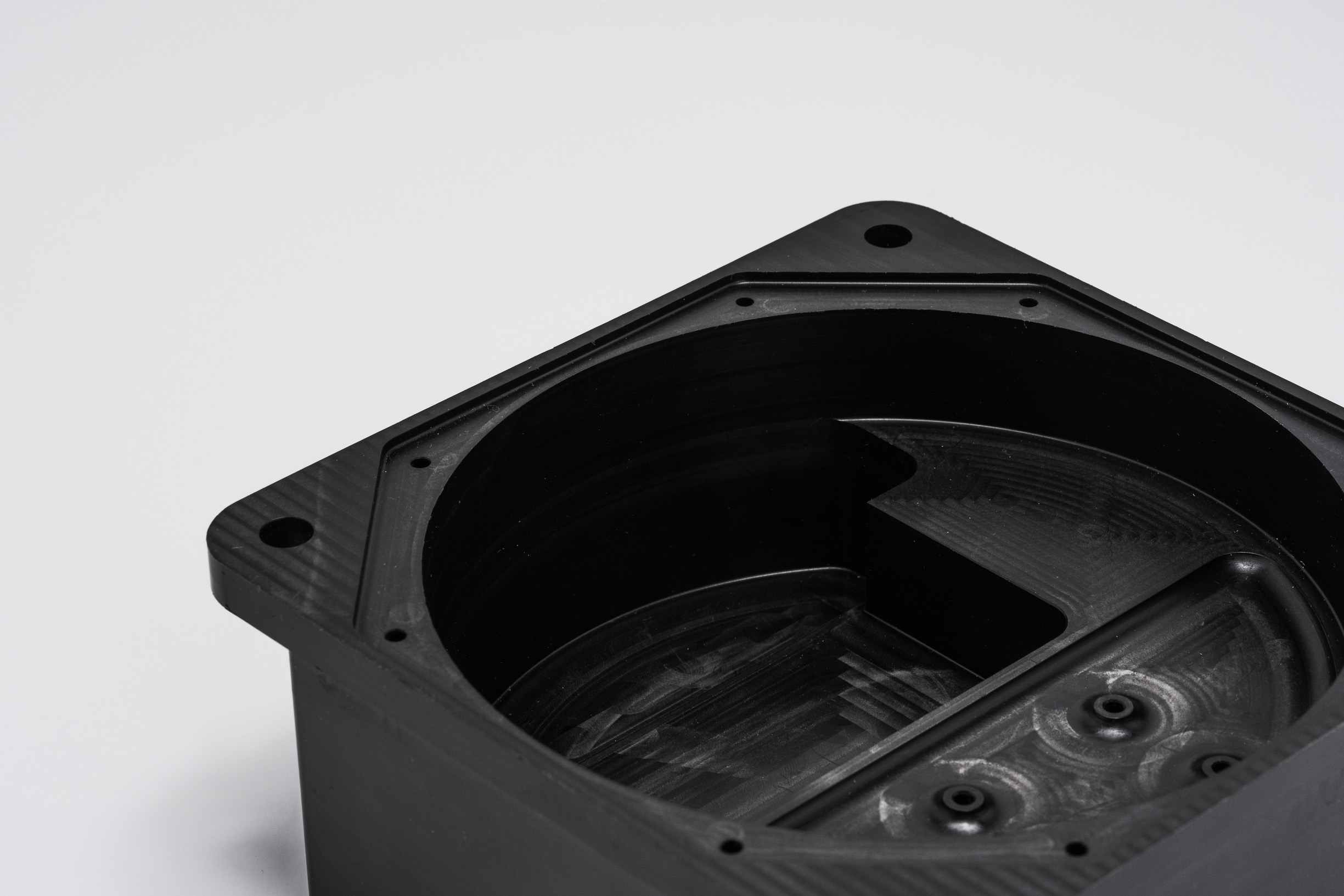

Pre-injection molding prototypes frequently employ the inexpensive engineering plastic ABS (Acrylonitrile Butadiene Styrene). ABS that has been CNC-machined is a fantastic choice for production-like products where attention to detail and mechanical qualities are crucial. ABS is only available in neutral and black colors.

ABS can be painted and has a somewhat matte surface (like Lego bricks). Additionally, ABS can be powder coated to increase its durability and UV resistance. Depending of their geometry and machining, some faces may appear more glossy. The finish of painted ABS parts will vary on the paint used.

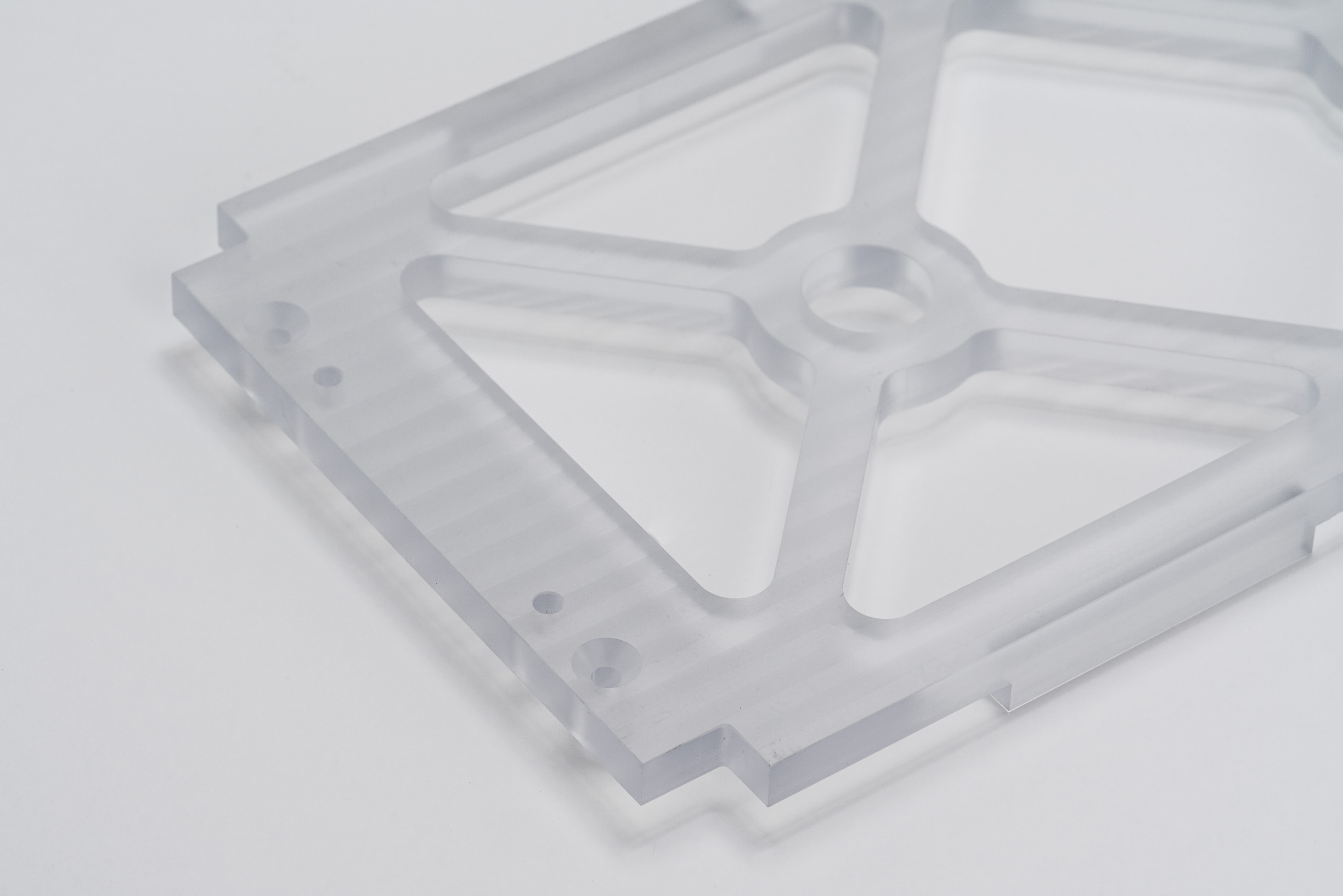

PMMA, which stands for polymethyl methacrylate, is another name for acrylic. Plexiglas and Lucite are also brand names for the material. A common application for this scratch-resistant plastic is in optical applications, tanks, and paneling. It is not advised for delicate or complicated geometries because it can become brittle in thinly walled sections.

In its unfinished condition, acrylic is either transparent or opaque (black, white, and a number of other hues). When machined, clear acrylic will seem frosted or translucent, but different finishing techniques can be used to polish it back to an optically clear state.

Because of its superior strength-to-weight ratio, low price, and ability to be recycled, aluminum is one of the most widely utilized metals in the world. Aluminum that hasn’t been treated often has a dull silver or grey sheen that varies based on the surface’s roughness. To create a variety of finishes, aluminum can be media-blasted, sanded, and hand-polished.

Every Apple laptop over the past ten years is anodized because it offers a number of color possibilities and gives a consistent, smooth feel to the entire device. Anodizing is a common process used to polish consumer goods made of aluminum. Alodine, which comes in clear or gold colors, is frequently used as an alternative protective coating to anodize on aluminum parts.

Due to its greatest lead percentage of any brass alloy, 360 Brass is also known as free-machining brass. There is little tool wear associated with this high machinability. It is utilized for many different parts, including gears, lock parts, pipe fittings, and decorative purposes.

Depending on the surface roughness, 360 Brass has a shiny yellow finish that changes in color. It can be media blasted for a matte texture or hand-polished to make it more shiny (like a trumpet or saxophone).

Bearing 932 Because it contains tin, iron, and zinc, bronze is a high strength alloy with good wear and corrosion resistance. The most typical applications are for thrust washers, bushings, and bearings. Heat treating 932 Bronze is not possible.

Depending on the desired surface quality, the shine of 932 Bronze, which is somewhat darker than copper, will vary. To change its aesthetic appearance, it can be polished or media-blasted.

The outstanding thermal and electrical conductivity of copper alloys 101 and 110 makes them the obvious choice for bus bars, wire connectors, and other electrical applications. Due to its purity (99.99% copper), 101 (also known as super-conductive copper) offers better conductivity, but 110 is typically simpler to process and therefore more affordable.

Depending on the procedure used to treat the surface, copper has a glossy reddish-orange sheen that varies slightly. To produce a variety of aesthetic finishes, copper can be media-blasted and polished.

A material with low friction and great rigidity is called Delrin (also known as acetal or POM, or polyoxymethylene). It is employed in a variety of products, including musical instruments and vehicle parts. Delrin exhibits outstanding dimensional precision, a reasonably high durability, and little elongation under stress.

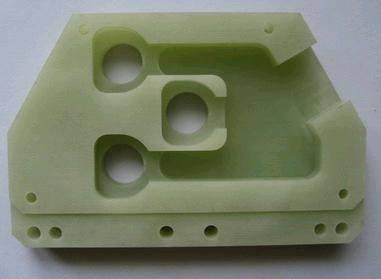

phenolic and epoxy-grade industrial laminate, also known as garolite G-10, is a composite material with a low coefficient of thermal expansion. It is also a great insulator and does not absorb water, making it ideal for electronics applications.

The colors of Garolite G-10 are typically opaque and range widely. When machined, it has a matte finish and is smooth.

A slick material known as high-density polyethylene (HDPE) is frequently manufactured into plugs and seals. HDPE is a superior electrical insulator and is resistant to chemicals and moisture.

Due of its crystalline structure, HDPE is naturally opaque white, although it is also available in more constrained stock sizes coloured black. It has a waxy finish that is used in applications that require low friction.

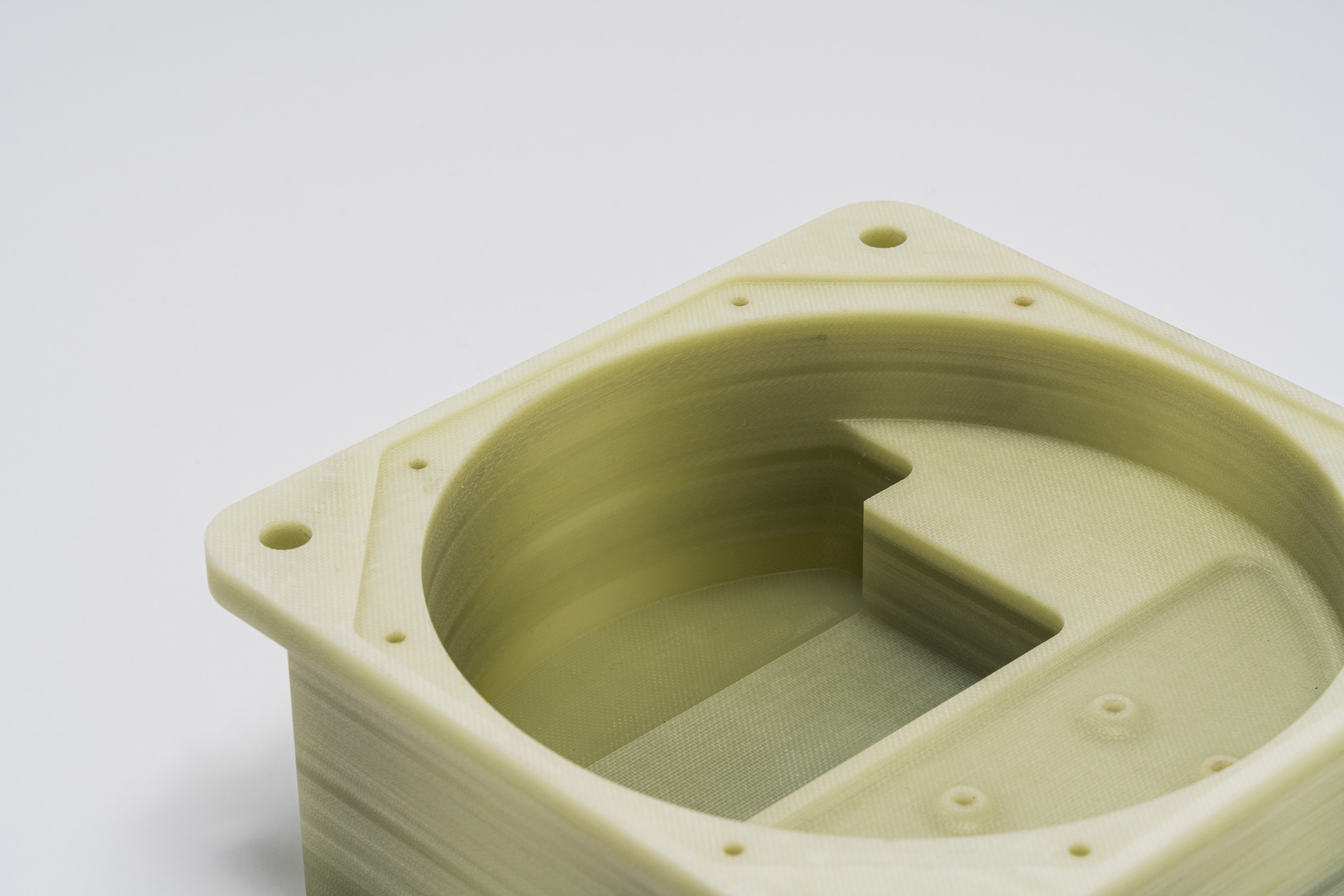

The Nylon family of plastics is particularly famous for its Nylon 6/6 material. It is robust enough to withstand permanent deformation under stress, stiff enough to hold its shape, and has a comparatively excellent chemical and heat resistance.

Nylon is most commonly used for screws and spacers on panel mounted circuit boards in the fields of medical devices and electronics insulation.

The many beneficial characteristics of glass-filled nylon include its high rigidity, strength, hardness, toughness, and dimensional stability. This substance can be utilized in assemblies that need electrical or mechanical insulation. Electrical housings, washers, medical gadgets, and aircraft components are a few examples of common applications.

Nylon is available in neutral (milky-white finish with a hint of translucency) and black hues.

PEEK (polyetheretherketone) is an excellent lightweight replacement for most soft metals in high-stress/high-temperature applications. PEEK is additionally resistant to moisture, abrasion, and chemicals. Due to its resistance to temperature change, PEEK is a good material choice for components with tight tolerances.

High-performance PEEK with glass filling has exceptional rigidity, strength, and toughness. Its capacity to maintain dimensional stability despite challenging thermal and chemical conditions is improved by the incorporation of glass fibers. This substance is frequently utilized in microwave, semiconductor, automotive, medical, and aerospace applications.

PEEK may be machined to a range of surface treatments and has an opaque beige color.

Polypropylene (PP), which withstands the majority of solvents and chemicals, is a material that is frequently used for laboratory apparatus and containers in a range of applications. Additionally, PP has an excellent fatigue strength and performs well for sections that are subjected to repeated loads and motions.

Although it also comes in opaque white, polypropylene is often a semi-clear white color.

High-performance engineering plastic with exceptional temperature resistance, dimensional stability, and electrical insulating qualities is polyphenylene sulfide (PPS). PPS is frequently used in high temperature applications such as automotive components, appliances, electronics, medical equipment, and industrial applications due to its superior mechanical strength, chemical resistance, and flame resistance.

When PPS is machined, the finish is opaque and off-white. After machining, it has a matte, smooth look, and depending on the situation, the surface finish can be made smoother or rougher.

Polytetrafluoroethylene, generally known as PTFE or Teflon, is a material that is highly insulating, chemical, solvent, and temperature resistant. Additionally, the plastic is slippery, making it an ideal choice for low-friction applications like bearings. PTFE is available in opaque black or white.

Steel has a finish that is comparable to stainless steel’s, usually glossy and a little darker than that of aluminum alloys. Media blasting or electropolishing are two methods that can be used to achieve different surface finishes on alloy and carbon steels. Fictiv provides several steel alloys, including:

Mild, low carbon steel, or 1018 steel, can be machined, welded, and used in applications where great strength is not necessary, including fixtures and mounting plates. This alloy can be heated treated and is magnetic.

Compared to carbon steel, 4140 alloy steel is often stronger and tougher. 4140 is a fantastic option for driveshafts, axles, and torsion bars since it also offers good impact resistance, fatigue strength, and torsional strength.

Steel has a finish that is close to stainless steel, and titanium grade 5 is the strongest titanium alloy available. It has good corrosion resistance and can be welded. Due to its relative lightness and resistance to both extreme heat and cold, titanium may be preferred over other materials like steel. Aerospace fasteners, turbine blades, engine parts, sporting goods, and maritime applications are a few examples of common applications.

In terms of general appearance, titanium is comparable to the majority of stainless steel grades. Titanium can be media blasted or tumbled to obtain a variety of surface qualities, and passivation can be used to apply a thin, protective layer.

The strong plastic known as Ultra-High-Molecular-Weight Polyethylene (or UHMW) has a slick surface and can withstand wear and abrasion. It is also the best material for machine guards and chute/hopper liners because of its excellent impact strength.

UHMW is opaque and available in black or white.

The PEI, or polyetherimide, brand name ULTEM 1000 is a translucent, amber-colored plastic with exceptional toughness, stiffness, and heat resistance. Due to its best dielectric characteristics, ULTEM 1000 is in some applications superior to Nylon and Delrin. Electronics, medical technology, and industrial equipment are examples of common applications.

ULTEM is smooth and slightly frosted when machined.

Steel is coated with zinc, commonly referred to as galvanization, to stop the surface from oxidizing or corroding. The item is covered in flux and then submerged in molten zinc to complete the process. The steel and molten zinc join together to form a layer of protection on the surface.

The component has a pale blue color thanks to clear zinc coating. Black Type II anodizing will seem comparable to black zinc plating in terms of color and finish.

Industries and Applications of C

Metal

Aluminum

Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

Aluminum

Stainless steel

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished.

Alloys

Stainless steel 416 | 1.4005 | X12CrS13

Stainless steel 15-5 | 1.4545 | X5CrNiCu15-5

Stainless steel 301 | 1.4310 | X10CrNi18-8

Stainless steel 430 | 1.4016 | X6Cr17

Stainless steel 440C | 1.4125 | X105CrMo17

Stainless steel 420 | 1.4028 | X30Cr13

Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9

Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3

Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 – Annealed state

Stainless steel 303 | 1.4305 | X8CrNiS18-9

Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

Mild steel

Mild steels are low-carbon metal alloys offering good mechanical properties, machinability and weldability at low cost. Can be carburized to increased hardness.

Alloys

Brass

Brass is a metal alloy with good machinability and excellent electrical conductivity. Ideal for applications that require low friction.

Alloys

Copper

Copper offers excellent thermal and electrical conductivity, it's often used for busbars, wire connectors, and other electrical applications. Copper has a glossy reddish-orange appearance.

Alloys

Copper C101 | CU OFECopper C110 | CU ETP

Alloy steel

Alloy steels contain other alloying elements in addition to carbon, resulting in improved hardness, toughness, fatigue and wear resistance.

Alloys

Alloy steel 1.7131 | 16MnCr5

Alloy steel 1215 | EN1A | 1.0715

Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Tool steel

Tool steels are metal alloys with exceptionally high hardness, stiffness and abrasion resistance. Suitable for manufacturing industrial tools.

Alloys

Titanium

Titanium is a metal with excellent strength-to-weight ratio, low thermal expansion and high corrosion resistance that is sterilizable and biocompatible.

Alloys

Inconel

Inconel is a high-strength, corrosion-resistant nickel alloy. Ideal for aerospace applications.

Alloys

Inconel 718

Invar

Invar is a nickel alloy with a very low coefficient of thermal expansion. Ideal for applications where high dimensional stability is required, such as precision instruments, engines valves and large aerostructure molds.

Alloys

Invar

Metal

G-10

G-10 is a high-pressure fiberglass laminate with a high strength, low moisture absorption, and high level of electrical insulation and chemical resistance.

Nylon

Nylon - polyamide (PA) - is an engineering thermoplastic with excellent mechanical properties and high chemical and abrasion resistance.

PPSU

PPSU offers exceptional hydrolytic stability, and toughness superior to other commercially-available, high-temperature engineering resins. They offer high deflection temperatures and outstanding resistance to environmental stress cracking. This polymer is inherently flame retardant, and also has excellent thermal stability and good electrical properties.

ABS

ABS is a common thermoplastic with all-around good mechanical properties, excellent impact strength, good heat resistance and good machinability.

PEEK

PEEK is a high-performance engineering thermoplastic with excellent mechanical properties and chemical over a very wide temperature range.

PTFE (Teflon)

PTFE is an engineering thermoplastic with excellent chemical and thermal resistance and the lowest coefficient of friction of any know solid.

Polycarbonate

Polycarbonate (PC) is a thermoplastic with high toughness, excellent impact strength and good machinability. Can be optically transparent.

Polyethylene

Polyethylene (PE) is a thermoplastic with high strength-to-weight ratio, good impact strength and excellent weather resistance.

PVC

PVC is the third most used plastic with all-around good mechanical properties, excellent chemical and weather resistance and good toughness.

PET

PET is a tough plastic that offers excellent wear resistance and mechanical strength.

G-10

G-10 is a high-pressure fiberglass laminate with a high strength, low moisture absorption, and high level of electrical insulation and chemical resistance.

FR4

FR4 is a class of glass fiber epoxy laminate that is flame retardant, with similar properties to G-10.

PEI

Characterized by a combination of outstanding thermal, mechanical and electrical properties, Polyetherimide (PEI) has made its place in high performance applications like automotive, aerospace, industrial and many more.

CNC Machining Materials

- Aluminium 2007 / 3.1645 / Al-CuMgPb

- Aluminium 2017A / 3.1325 / Al-Cu4Mg

- Aluminium 6060 / 3.3206 / Al-MgSi

- Aluminium 6061 / 3.3211 / Al-Mg1SiCu

- Aluminium 6082 / 3.2315 / Al-Si1Mg

- Aluminium 7075 / 3.4365 / Al-Zn6MgCu

- Steel 1.0038 / S235JR

- Steel 1.0503 / C45

- Steel 1.0511 / C40

- Steel 1.0570 / S355J2G3

- Steel 1.2842 / 90MnCrV8

- Steel 1.7131 / 16MnCr5

- Steel 1.7218 / 25CrMo4

- Steel 1.7225 / 42CrMo4

- Stainless Steel 303 / 1.4305 / X10CrNiS18-9

- Stainless Steel 304 / 1.4301 / X5CrNi18.10

- Stainless Steel 304L / 1.4307 / X2CrNi18-9

- Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

- Stainless Steel 316Ti / 1.4571 / X6CrNiMoTi17-12-2

- Copper E-Cu57 / 2.0060 / E-Cu58 / 2.0065

- Brass Ms58 / 2.0401 / CuZn39Pb3

- Titan Grade 2 / 3.7035

- Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

- ABS

- Acrylic

- Industrial PEEK

- Nylon 6 / PA 6

- PC (Polycarbonate)

- PEEK glass-filled

- Polypropylene (PP)

- POM / Delrin acetal

- PTFE / Teflon

- PVDF / Polyvinylidene fluoride

- UHMW PE / Ultra-high-molecular-weight polyethylene

Finishing Options for CNC Machining

This is a finish option with the fastest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request.

- Zinc Coating / Galvanising

- Electroless Nickel Plating

- Anodising: Hard & Colour (Black Hardcoat, Black, Blue, Gold, Grey Hardcoat, Green, Natural Hardcoat, Natural, Orange, Red)

- Passivation

- Polishing / Electropolishing

- Bead Blasting

- Painting & Powder Coating

- Case Hardening

- Quenching and Tempering

- Normalising and Tempering

- Annealing

Additional processing and finishes on request.

Finishing Options for CNC Machining

| Name | Applicable Materials | Colors | Can be applied with | |

|---|---|---|---|---|

| Alodine | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — | — |

| Hand Polishing | Acrylic | — | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | Black (20% or 90% gloss), white (20% or 90% gloss) | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | — | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Clear: light blue coating, black: glossy black coating | Media Blasting, Tumbling, Passivation |

* = requires masking

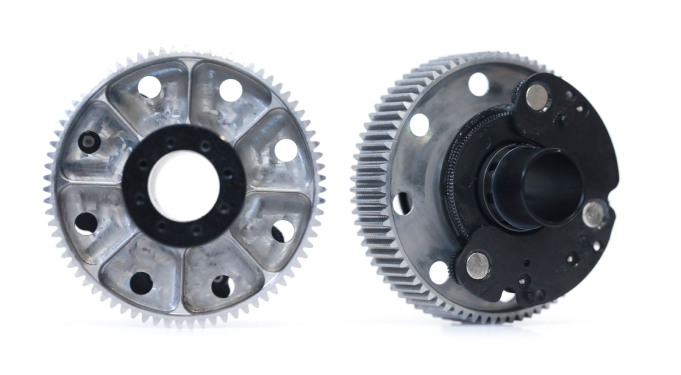

“Being able to use Fictiv for gears is very exciting. We know they're going to hit their lead times and we're going to be in constant communication to see where our parts are in the supply chain.”

Andrew Willig

Mechanical Engineer, HEBI Robotics

+/- 0.0004" tolerances

6 weeks for 650 gears

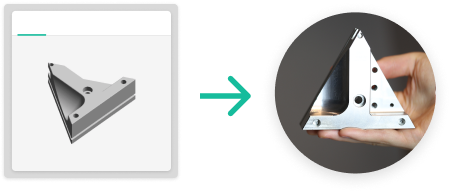

From Prototype to Production

Mid Stage Prototypes

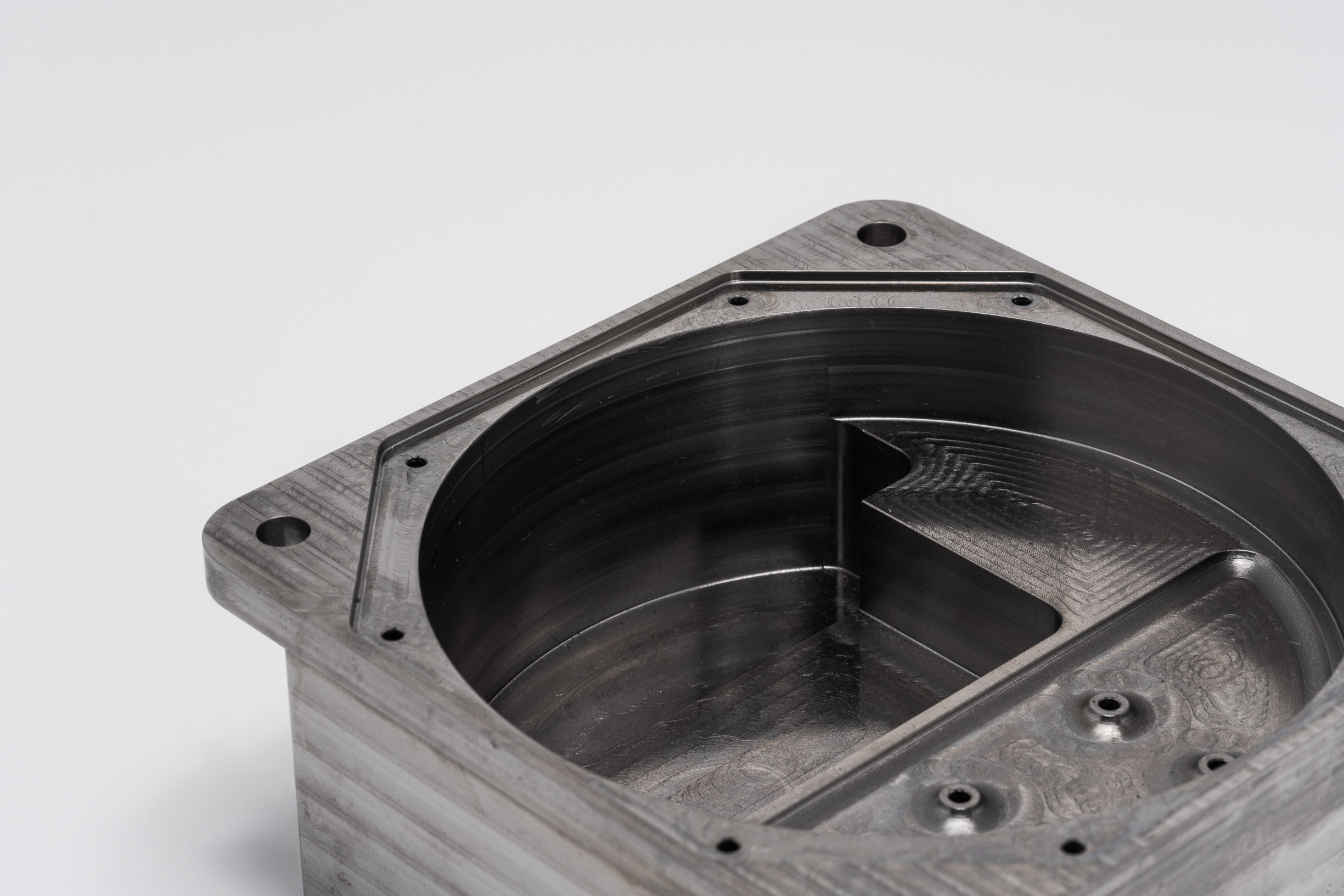

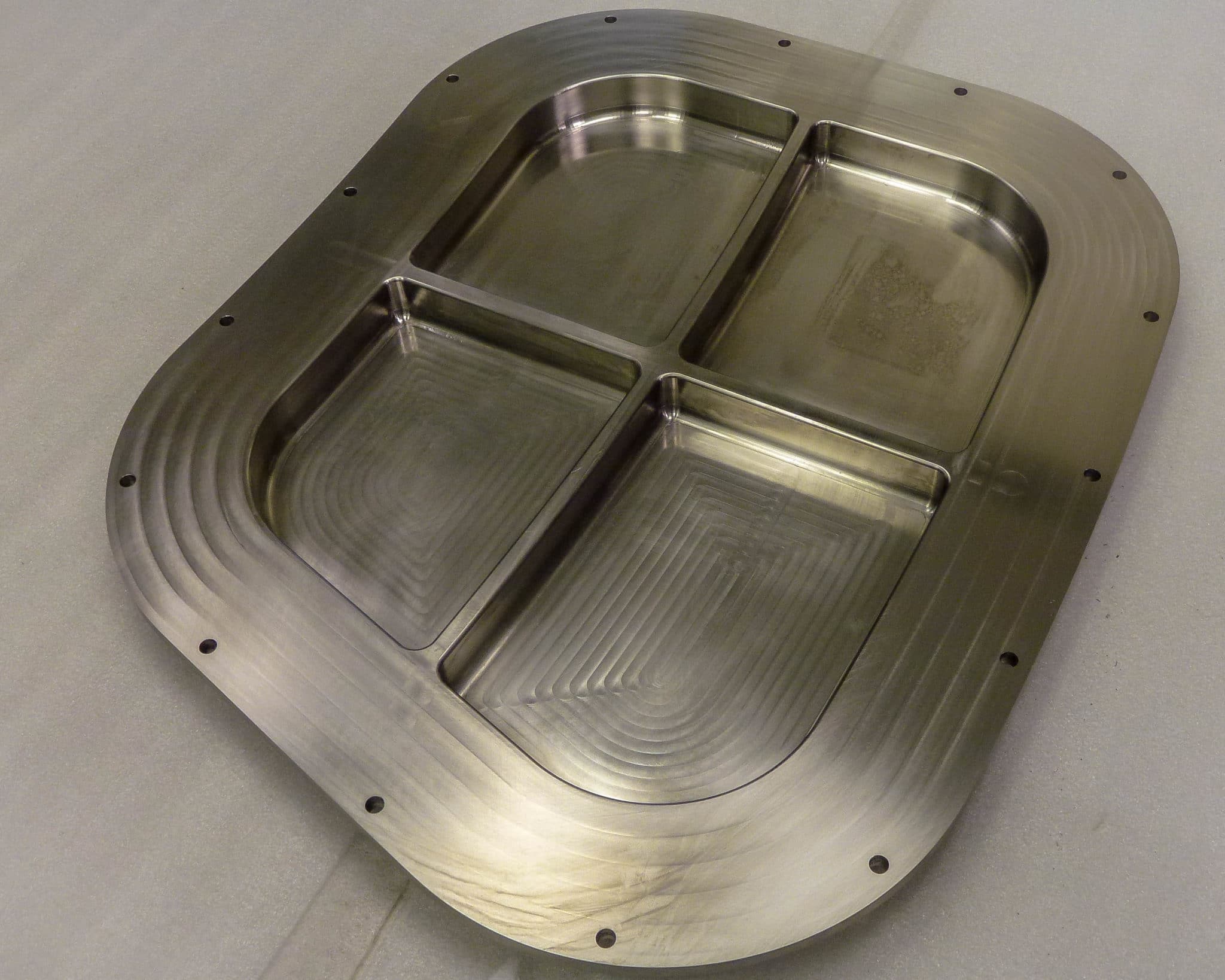

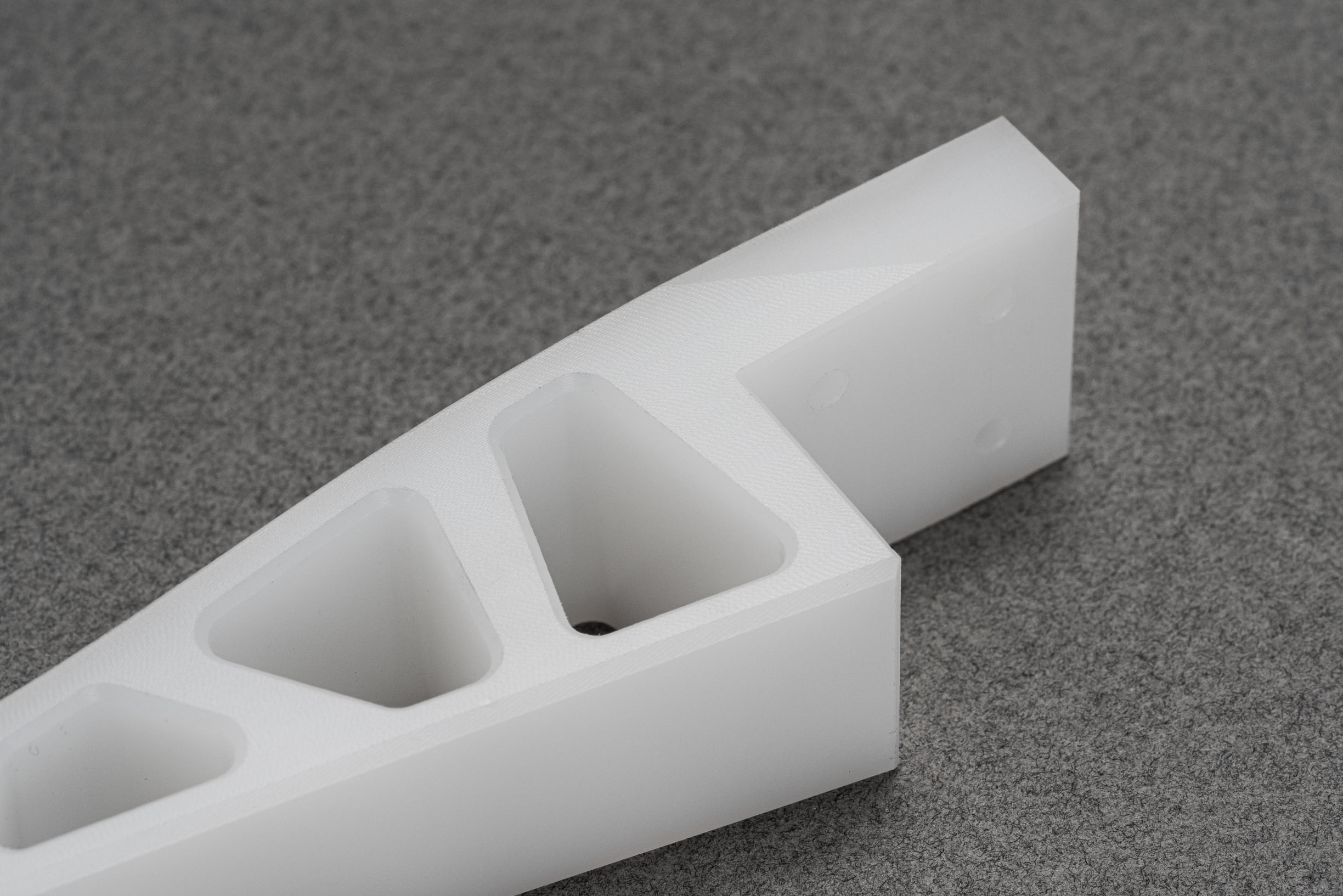

Prototype CNC machining is an ideal process for mid-stage functional prototypes. Fictiv can help you accelerate development cycles with rapid prototyping by providing instant online quotes, intelligent DFM feedback, and quick lead times.

- Finishing, masking & hardware installation

- CNC Milling, CNC turning, gear hobbing, EDM

- Tolerances as tight as +/- 0.0002″

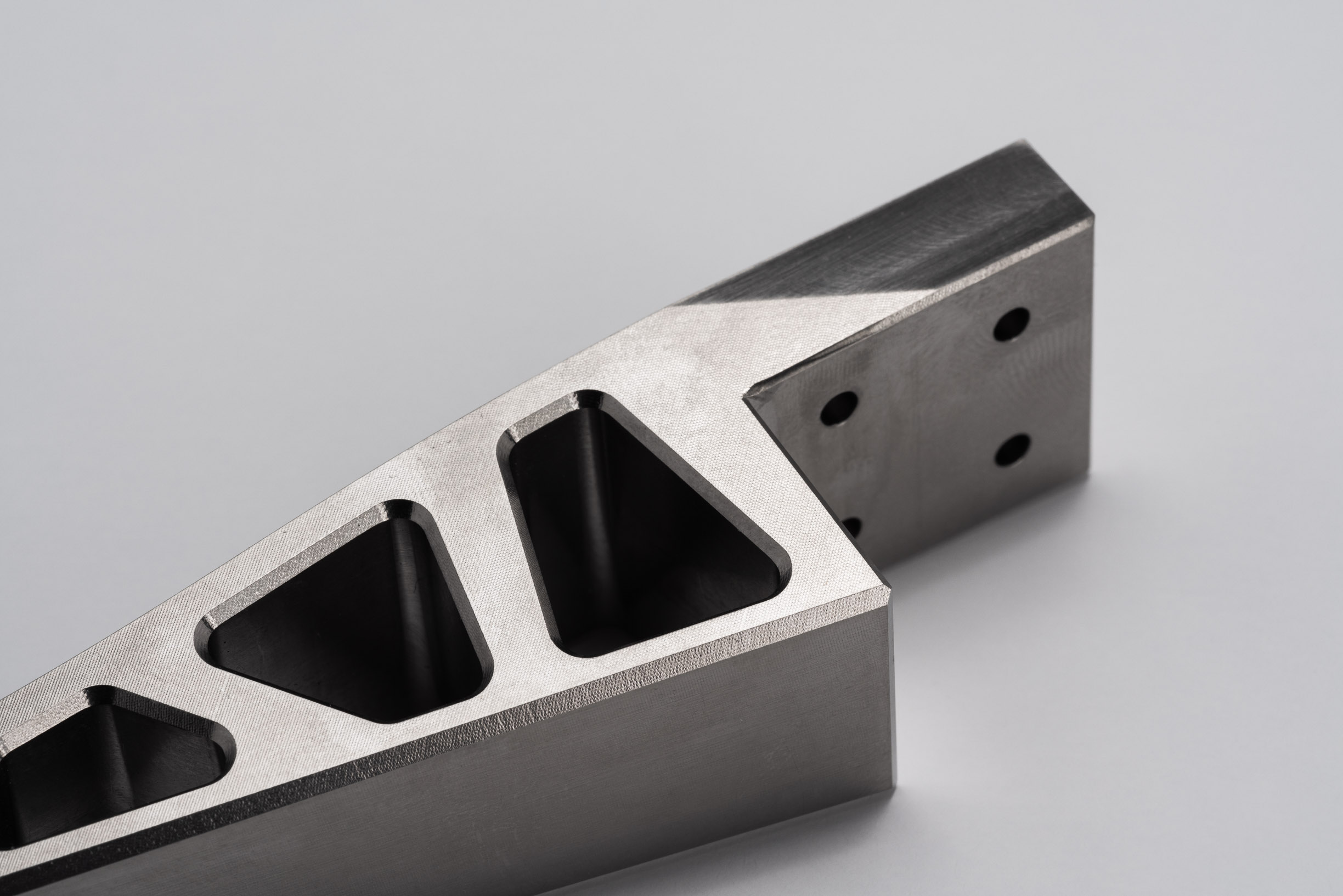

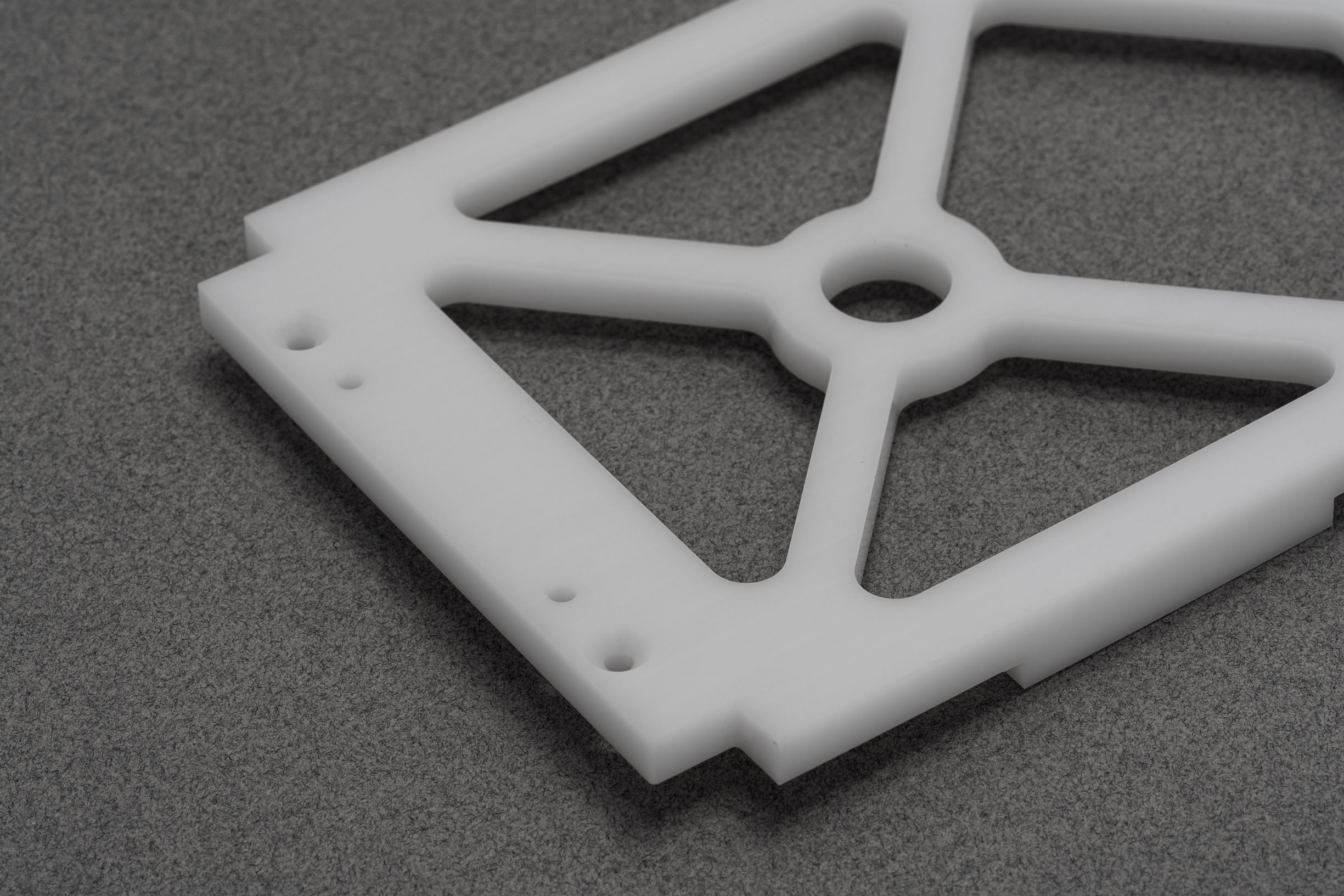

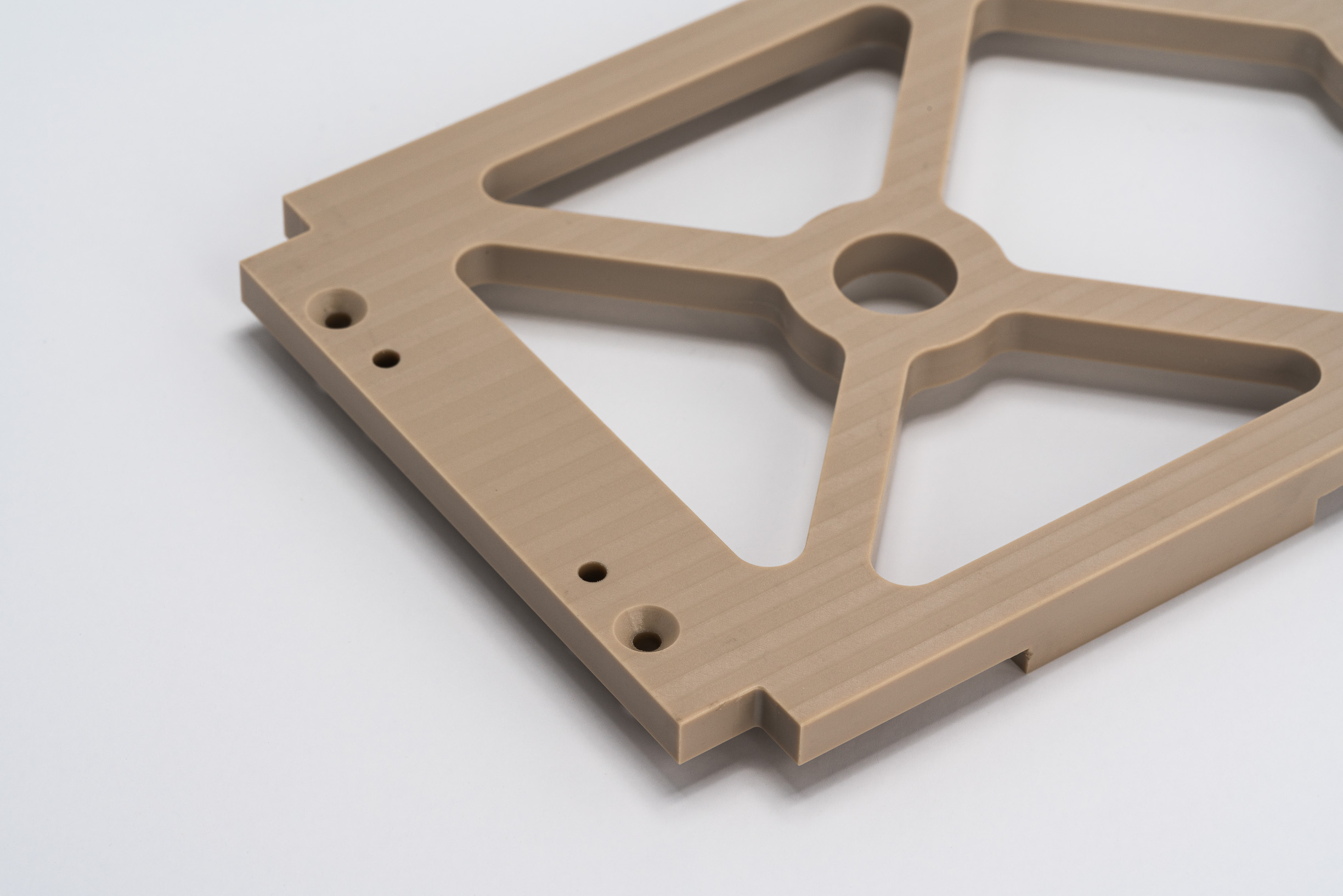

Production Parts

Custom CNC machining is often leveraged for end-use production grade parts. Fictiv’s global manufacturing network is optimized for production machining, with volumes up to 1M units.

- Inspections using CMM or laser scanners

- Material certification available

- ISO 9001 certified, AS 9100 / ISO 13485 compliant

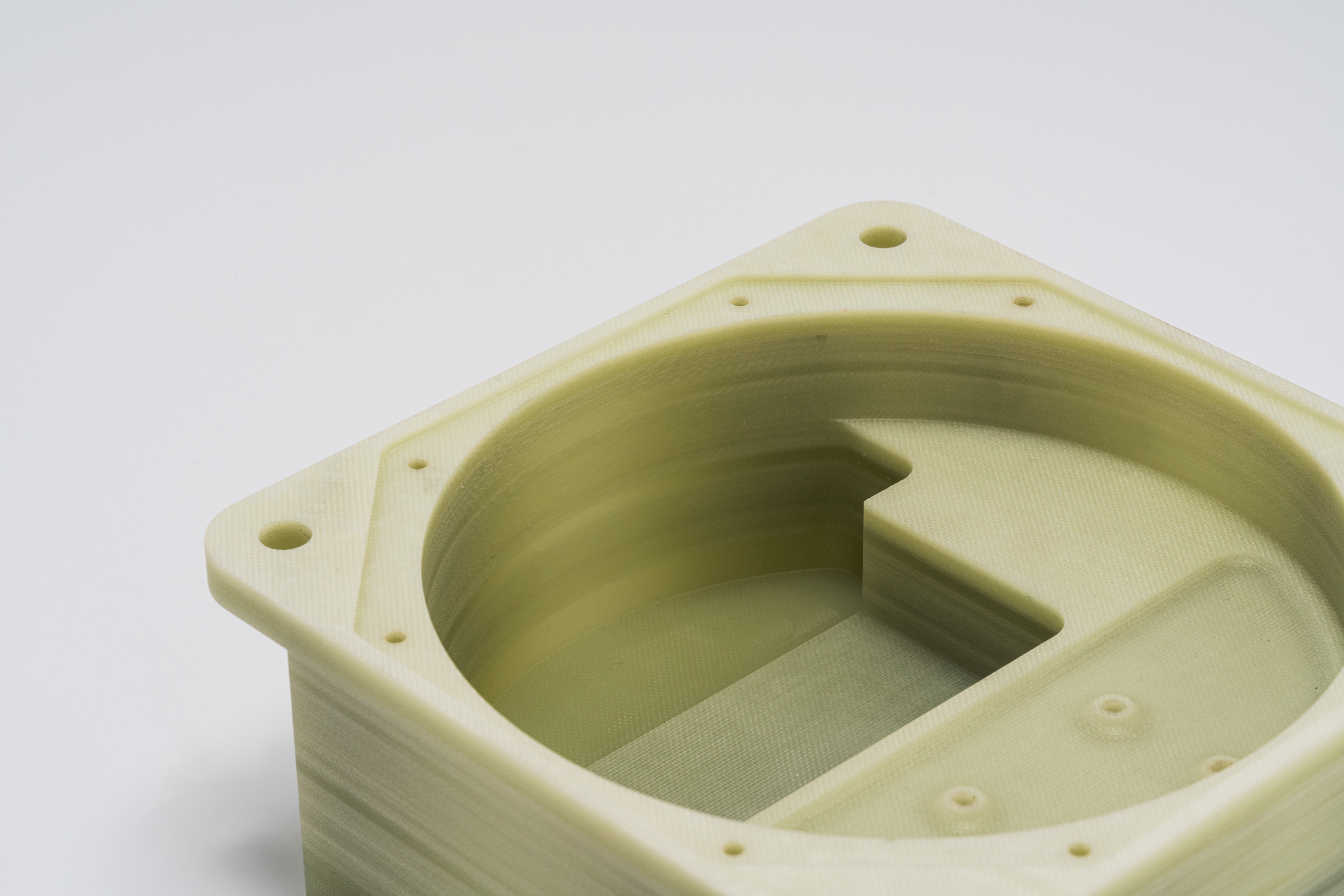

Production Tooling

Online CNC machining services are ideal for manufacturing components needed for production, including fixtures, jigs, gauges, molds, dies, cutting equipment, and patterns.

- Vetted partners in the U.S. and overseas

- Economical pricing options

- 2D drawings accepted

Our Quality Promise

- Inspection reports included with every order

- All CNC-machined parts inspected using hand metrology, CMM or laser scanners

- All manufacturing partners are highly vetted and managed

- ISO 9001 certified, AS 9100 & ISO 13485 compliant

- Quality guaranteed. If a part is not made to spec, we’ll make it right.

- Material certifications available

What is CNC Machining

What is CNC Machining?

CNC stands for computer numerical control. So, CNC machining is any kind of machining process controlled by a computer. Computerized automation allows parts to be made more quickly, accurately, precisely, and with more complex geometries than those produced via manual machining. CNC also reduces manual machining labor that would otherwise be done by humans. While they aren’t machining each part themselves, people are essential for programming and operating the machines, ensuring that every operation goes smoothly.

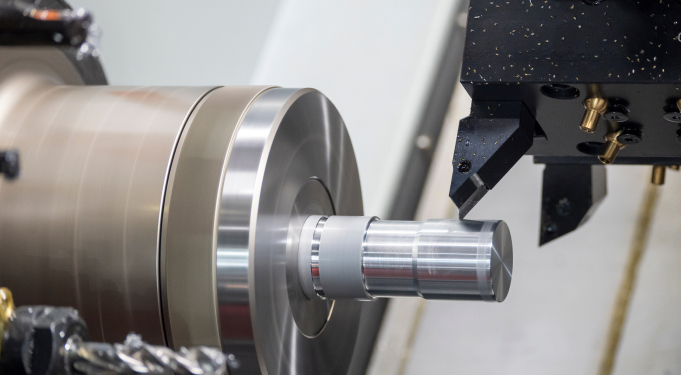

About the CNC Machining Process

CNC, or computer numerical control machining, is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to remove layers from a solid block of material. The desired cuts in the metal are programmed according to corresponding tools and machinery, which perform the machining task in an automated fashion.

Types of CNC Machining

Depending on the type of part that needs to be machined, there are different types of CNC machines best fit for the job. CNC milling utilizes CNC mills, which consist of a multi-axis system (three, four, or five axes, depending on the part complexity). CNC turning involves Lathe machines, which generally have 2 axes and cut pieces using a circular motion. Electric discharge machines (EDM) utilize electrical sparks into order to mold work pieces into the desired shape. Hobbing is another type of machining process used for cutting gears, splines, and sprockets. Additional CNC machine types include plasma cutters and water jet cutters.

How Does CNC Machining Work?

The programs used for CNC machining these days are written with G-code, and are usually automatically created by CAM software. CAM, or computer aided manufacturing software, generates the G-code for a 3D model with given tools and workpiece material. This G-code controls the CNC machines, i.e., the motion of the tool, the workpiece, and any tool changes. It even has commands to turn on or off the coolant and other auxiliary components.

CNC machining can be used for a wide variety of materials, with the most common being aluminum, steel, brass, ABS, Delrin, and nylon. But really, almost any hard material can be CNC machined. We’ll discuss materials more in depth later on.

CNC vs 3D Printing

Compared with parts manufacturing through additive methods, CNC machined parts are functionally stronger and typically have superior production quality and finish. Thus, CNC machining is typically used in the mid to late stages of development when parts are ready to be tested for functional accuracy.

CNC Design Considerations

While most of the details, such as tooling, spindle speed, cutter type, and depth of cut, and taken care of at the machine shop, there are some key things you can do while designing your parts to not only make sure they can be made, but also ensure you develop a lean product that doesn’t break the bank.

CNC Machining FAQs

Prices range from $65 to $125 depending on complexity, quantity, and lead time. Sending in a 3D CAD model and receiving an interactive quote with design for manufacturability (DFM) comments is the best method to find out. There are no upfront non-recurring engineering (NRE) costs because we use proprietary software and automated fixturing methods. This reduces the cost of acquiring amounts as low as 1 to 200 components. While costs are comparable to or somewhat higher than with 3D printing, machining gives better material characteristics and surfaces.

Expanded capabilities, tighter tolerances, volume pricing, and the capacity to handle more complicated parts are all provided through our global network of premium manufacturing partners driven by Hubs. For a complete list of the capabilities offered by Hubs, go to hubs.com and click on the ‘Capabilities’ tab in the navigation bar at the top of the page.

CNC Part Complexity Quiz

Looking for a way to quickly and easily determine how complex your CNC

machining part is? Look no further!