- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

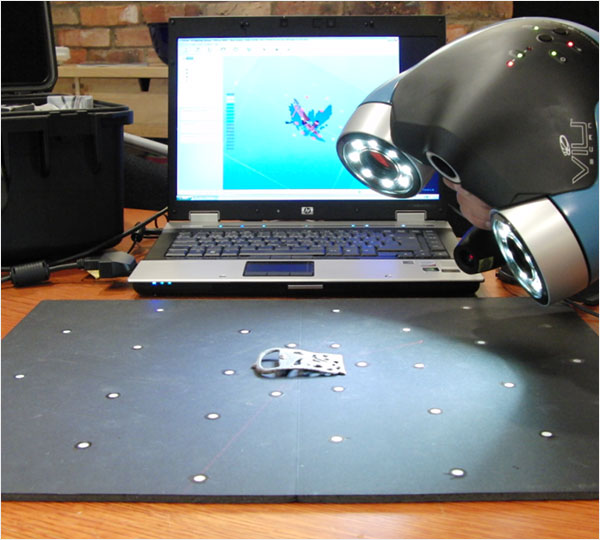

Do you wish to hasten the gathering of vital data to facilitate reverse engineering? Do you wish to increase the effectiveness of your construction projects? The most effective answer for you is 3D laser scanning technology. Our 3D laser scanning services can work remotely at your facility with cutting-edge 3D laser scanners and skilled operators to measure the necessary data with great accuracy and excellent detail in a short amount of time. Then, 3D modeling experts can create a precise 3D model based on the point cloud data formed from 3D scanning.

You can utilize the laser scan data to check the print dimensions, look into product troubleshooting, create CAD models, and conduct competitive analysis after we transform the scan data into operational deliverables. We will give you access to on-site intelligence regardless of whether your project merely requires scanning or a variety of services. We can satisfy your needs for data delivery and make sure that your timeline is on track to achieve your objectives. This includes scanning, visualization, and data processing.

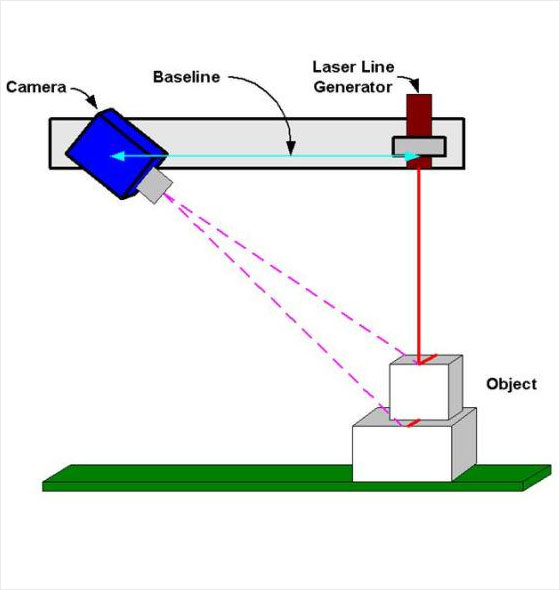

By using a high-speed laser scanning measurement technique, 3D laser scanning is a type of non-contact modeling technology that can swiftly gather the coordinates, reflectivity, color, and other details of each point on the object surface in a vast area and high resolution. A 1:1 true color three-dimensional point cloud model can be swiftly created from this vast and dense set of point data to serve as an accurate starting point for further processing and data analysis. Rapidity, high benefit, non-contact, penetration, dynamic, initiative, high density, high precision, strong digitization, automation, and real-time are some of its distinguishing characteristics. An effective and dependable method for extracting digital design files from solid items is 3D laser scanning.