Manufacturing relies heavily on CNC lathe equipment. In several industries, they changed the way we produce goods. These devices, which are accurate and productive, are shaping modern production. Autos, aircraft, medical, and electronics are just a few of the industries that employ them. CNC lathe equipment enables us to accurately and precisely create intricate pieces.

Parts of a CNC Lathe Machine

Let’s look at the key parts that make these machines so amazing:

Bed

The bed is the strong base of the CNC lathe machine. It holds all the other parts. It’s made from strong materials like cast iron, and it helps the machine move smoothly and accurately.

Headstock

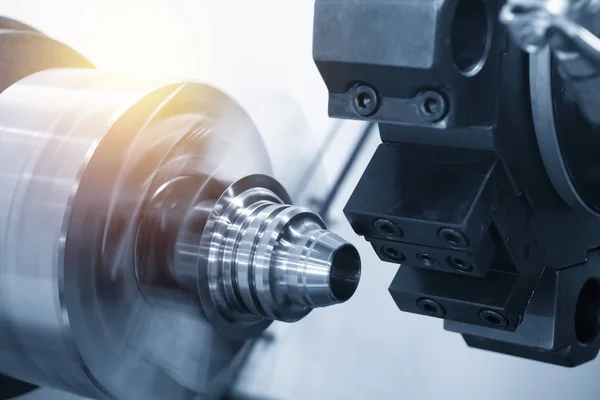

The headstock is the heart of the CNC lathe machine. It has the main spindle, which spins the piece we’re working on very fast. This spinning is important for cutting and shaping the piece to make the part we want.

Tailstock

The tailstock is opposite the headstock. It helps balance and support the piece we’re working on while the machine is running. It stops vibrations and makes sure the cutting is accurate. It’s like a helping hand that keeps everything in the right place.

Tool Turret

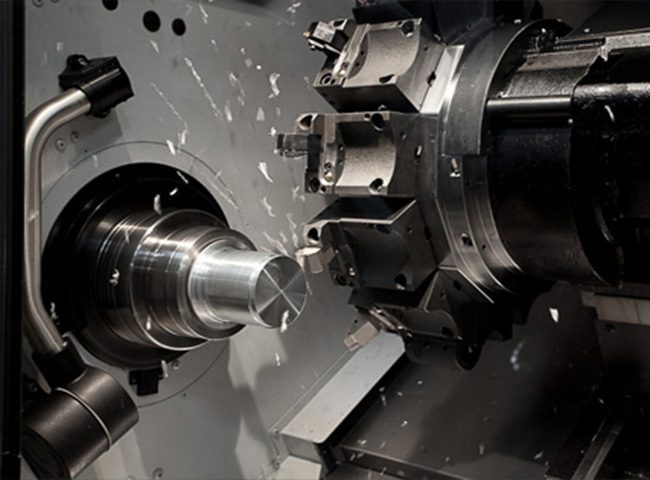

The tool turret is where the real work happens. It holds many cutting tools that can be moved and positioned automatically. This means the machine can work efficiently without needing to change tools by hand, saving time and making the machine more productive.

Control Panel

The control panel is like the brain of the CNC lathe machine. This is where operators put in commands, set up the machine, and watch the machining process. It’s easy to use and understand, so operators can program and control the operation without any trouble.

Workpiece Holder (Chuck or Collet)

Finally, we have the workpiece holder. Whether it’s a chuck or a collet, this part holds the piece we’re working on securely in place. This allows for accurate machining. It’s like a firm handshake between the machine and the piece, making sure everything is stable and accurate while the machine is running.

How Does a CNC Lathe Machine Work?

Ever wondered how we make detailed metal parts? CNC lathe machines do this job! They make precise parts used in many industries. Let’s see how this process works:

Programming the Machine

First, the CNC lathe machine needs instructions. This is where programming comes in. Operators put the design details into the machine using special software. It’s like giving the machine a plan to follow.

Loading the Workpiece

After setting the program, it’s time to put the workpiece on the machine. The workpiece is the material that we will shape into the part we want. It could be metal, plastic, or even wood. Putting it on the lathe carefully is very important for a successful job.

Setting Up Tools

Tools are the hands of the CNC lathe machine. They cut, shape, and drill the raw material to make the finished product. Before starting the job, operators must put the right tools on the lathe. This makes sure the process is precise and efficient.

Running the Job

With everything ready, it’s time to start! The CNC lathe machine starts working, following the programmed instructions exactly. It spins the workpiece while the tools move accurately along its surface, cutting out the shape we want. It’s like watching a sculptor make a masterpiece, but with metal instead of stone!

Unloading Finished Parts

It’s time to examine the outcome once the work is over. The CNC lathe produces completed parts that will be ready for use. When removing them from the machine, the operators take great care to ensure that everyone is flawless. Opening a present is similar, except you know precisely what’s inside!

Uses of CNC Lathe Machine

CNC lathe machines are more than just tools. They are the heart of modern making in many industries. Let’s see how these handy machines are used in different areas:

Car Industry

In the car industry, we need to be exact. CNC lathe machines help with this. They make important parts like crankshafts, camshafts, brake rotors, and transmission parts. These machines help make the detailed parts that keep cars working well.

Aerospace Industry

In aerospace, safety and trust are very important. CNC lathe machines help make exact parts for aircraft engines, landing gear, and structure parts. Whether it’s making turbine blades or detailed aerospace parts, CNC lathes make sure the quality and performance are top-notch.

Medical Device Making

In the medical field, being exact and consistent is very important for patient safety. CNC lathe machines help make many medical devices. These include surgical tools, implants, prosthetics, and orthopaedic parts. With CNC lathes, medical device makers can make complex, custom parts very accurately.

Electronics Industry

In the fast world of electronics making, being exact and efficient is key. CNC lathe machines help make parts like connectors, sockets, and housings for electronic devices. These machines make sure the parts are made just right and have a smooth finish. This is very important for the smooth working of electronic gadgets and equipment.

General Machining Workshops

CNC lathe machines are also found in general machining workshops. These workshops work for many industries, from furniture making to agricultural equipment making. CNC lathes help these workshops do many machining jobs. These range from simple turning jobs to making complex parts. They do all these jobs easily and exactly.

Final Words

CNC lathes play a vital role in production. In today’s industrial operations, they are vital because of their accuracy, uniformity, and adaptability. They add to better efficiency and guarantee quality. With its ability to stimulate innovation and progress across all industries, CNC lathe machines are completely changing the face of manufacturing. Using CNC lathe equipment is not just a possibility if you want to stay competitive in the current industrial business.