Welcome on behalf of the exciting world of CNC machinery! Imagine a machine making nearly anything you like from wood, plastic, or metal. That is the nature of CNC machines! These brilliant gadgets use digital signals to cut and form things. Whether you’re an adult or thinking of your next big design, this machine is for you. For many who are unsure about making handles, CNC machines are like unique wands. They allow the change of ideas into visible, actual things. All the while, it is swift and exact, and it will enable you to go over each move without making any mistakes. Let’s start on this trip to find out how it runs and why it is vital to create cool things around us!

What are the basics of a CNC machine?

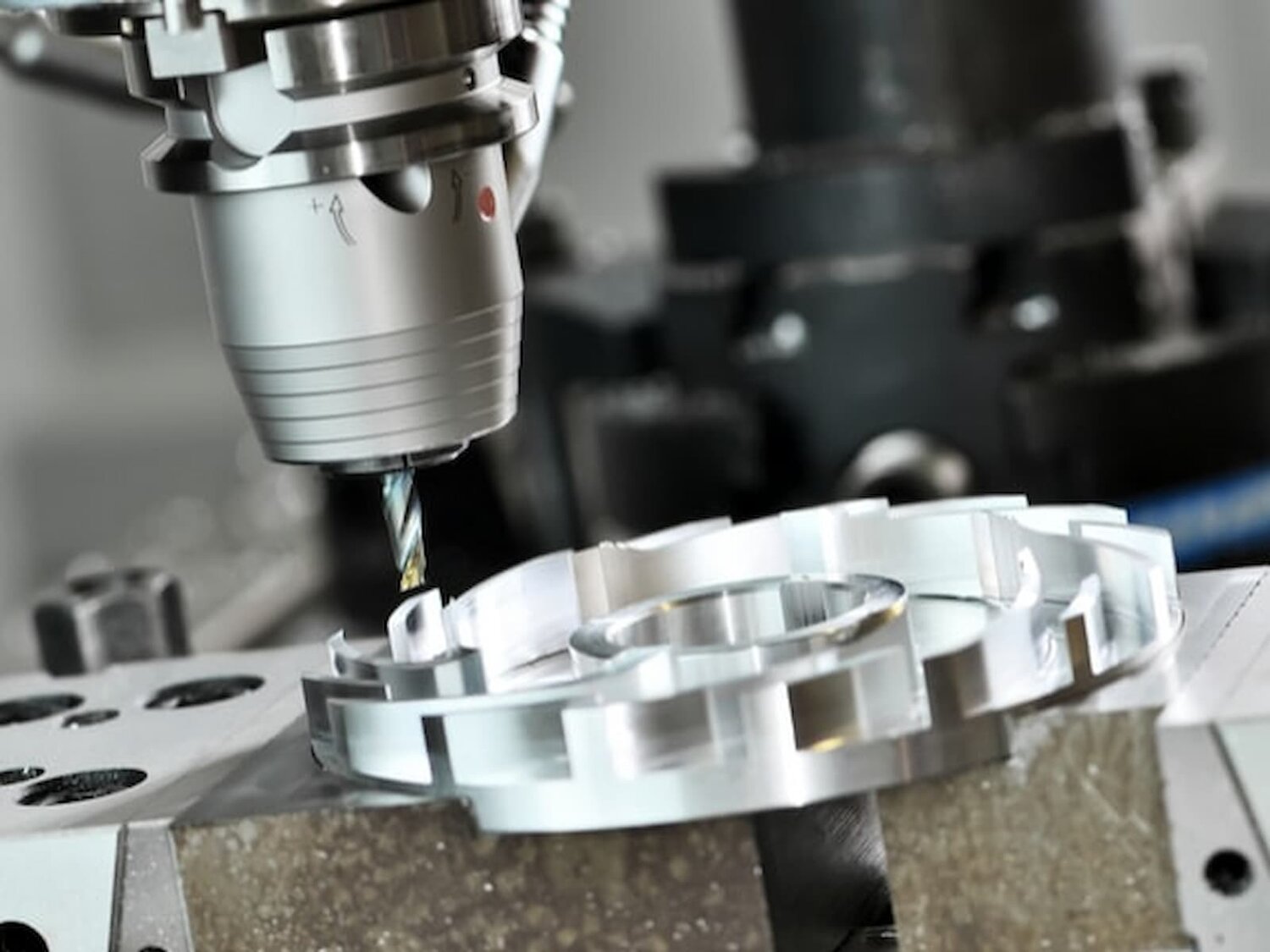

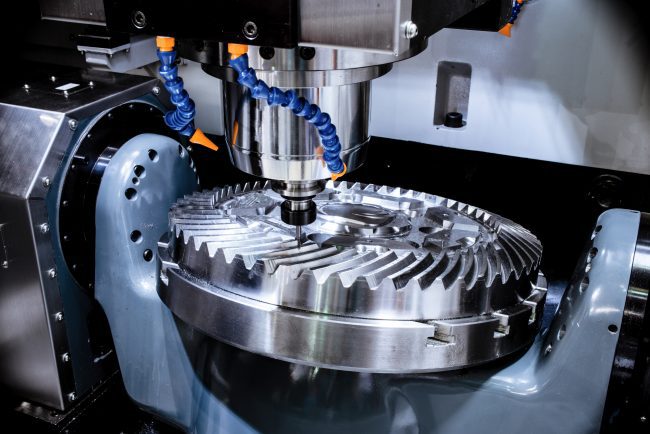

Advanced machinery used in industry is known as a CNC machine. It runs by receiving orders from a machine. With fantastic clarity, it makes cuts in materials like plastic, wood, and metal. Many different kinds of CNC machines can be used for every type of task. Making a turn, cutting routes, and plasma or cutting by laser can all be likely with such tools. These gadgets save energy and avoid errors by performing tasks by hand. Various kinds of industries use them. They also created electronics and furniture in addition to auto and aeroplane parts. CNC machines are high-precision machines, which lead to better and faster tasks!

What CNC machine should I buy?

Getting the ideal tool for a big job is like getting the right CNC tool. It’s vital to consider your wants, aims, and budget. Making it simple for anyone to grasp, let’s break it out into manageable steps:

Assess your needs

Materials: Decide what you wish to shape or cut. Some stuff, such as plastic, metal, or wood, works well with various tools.

Project Types: Take notice if you’re making intricate designs or basic shapes. A more modern machine might be needed for larger tasks.

Density and Force

Which Is the Area of Your Space For? Check if the device will fit in the area of work. Verify if there’s enough power in the area for the device to work.

Energy for Your Tasks: A giant machine needs power for supplies because of its strength. More energy may also be required for more significant tasks.

Machinery Types

Milling machines have a lot of uses. A wide array of things can be cut by it.

Lathes: These can be great instruments to create round items.

Routers: These are ideal for using plastic, foam, and wood.

Metal cutting is a terrific application for plasma cutters.

Cool Stuff

Speed: multiple devices have various times of activity. For your tasks, going faster could be ideal.

Making fancy cuts: You may need a flexible machine to make tricky objects.

When working with computers, verify that the tool is compatible with the software.

Economics

Getting the Machine: Assess the cost before making an offer.

Maintaining It: Pay attention to the costs of basics like electricity. And repair whatever is harmed as needed.

Recouping Investment: Consider how the machine will let you make more unique items.

Help and Salary

Getting Help: Consider if you can quickly get help or advice on using the machine.

Warranty: Try for an object that has a warranty. And it will be replaced or fixed in cases where anything goes wrong.

What Are Others Saying?

Reviews: Find out what others have to say about the gadget. Knowing how it works well and what doesn’t is helpful.

Speak with the experts: Check out what the experts you know have to say about these items.

Think Before Buying

Observe it in Step One: Keep an eye on the device while it works to ensure it meets what you want.

Test with Your Things: See how the machine performs on your supplies by seeking to use them in it.

Lastly, choosing a CNC machine is a vital choice. Still, you can find the right one for your tasks if you think about what you need. It is similar to picking the right dance partner. Pick the one that fits your steps, and together, you will make lovely items.

What is the best location for a CNC machine?

If you are seeking an excellent CNC machine, seek a place with a large selection. Besides being highly useful if you require it, they also need to have tools for cutting metal or wood. There’s plenty to see at XIDIBEI. Their client service is excellent, and they have lots of machines. Their website has plenty of data. You can ask queries about different tools to learn about them. It might be an ideal place to start if you’re seeking a CNC machine in XIDIBEI.

FAQs

What’s a CNC machine?

It’s an intelligent machine that cuts and shapes stuff super accurately, controlled by a computer.

What parts does a CNC machine have?

It has a brain (control unit), muscles (motors), tools, holders for things being worked on, and a cutting tool.

What can it work on?

Metals, plastics, woods, and more. If it fits, it can be shaped.

What support and training options are available?

Manufacturers offer help over the phone or online, and some provide on-site training.

How essential are software and user interfaces?

It’s crucial for easy programming and operation.

Can I customize a CNC machine to meet my needs?

Yes, many machines can be customized with extra features or tools.

Conclusion

Lastly, consider your price range when selecting which CNC machine you want to buy. Think about what you want to use it for and your needs for quality, too. Analyze factors such as system reliability, spinning power, and device size. For help with your choice, visit experts, review feedback, and view samples. Ensure that it fulfils both current and potential needs. Getting an ideal CNC machine requires finding the right balance between price and features. Also, it satisfies your manufacturing needs and your future advantages.