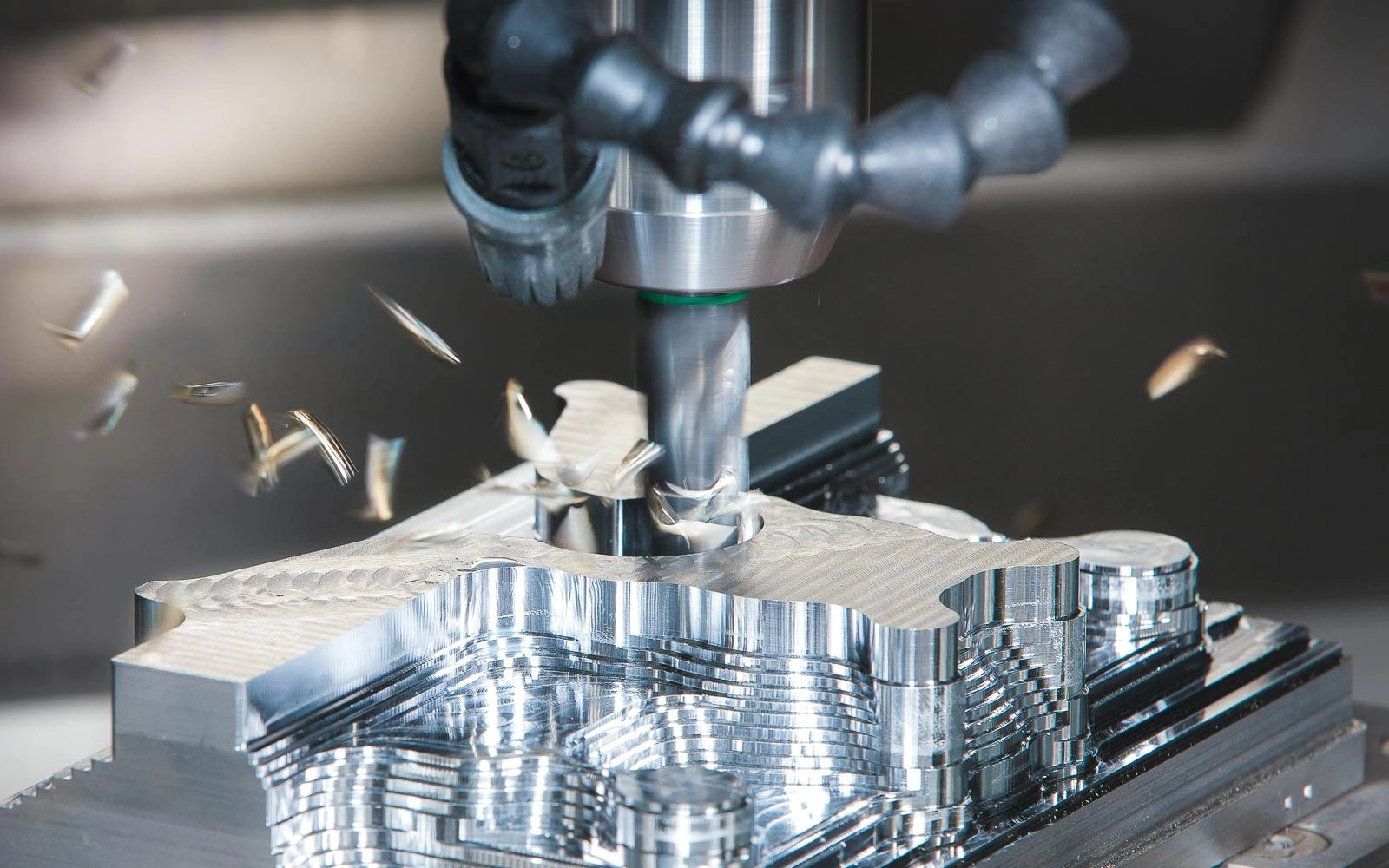

CNC (Computer Numerical Control) machines have revolutionized production globally. They permit specific and complex reducing, drilling, and shaping of materials like metallic, wood, and plastic. Among these machines, the 10-axis CNC system stands out because of its high-quality skills. But what angles can a 10-axis CNC machine do? Let’s dive into this subject matter and discover the charming international of 10-axis CNC machines.

Understanding a 10-Axis CNC Machine

Before we speak about the angles a ten-axis CNC device can acquire, allow us first to recognize what a 10-axis CNC machine is. The period “10-axis” refers back to the wide variety of different directions the machine can move or rotate a part all through machining. These machines can flow in extra ways than less complicated machines like 3-axis or five-axis machines.

In a 10-axis CNC system, there are usually six linear axes and four rotational axes. The linear axes move in direct lines, at the same time as the rotational axes rotate around special factors. This combination allows the machine to technique the material from simply any path.

What Angles Can a 10-Axis CNC Machine Do?

The fundamental benefit of a ten-axis CNC machine is its capability to paint at a variety of angles, thanks to its multiple axes. Let’s spoil down what angles this device can take care of:

Linear Movements at Any Angle

The linear axes on a 10-axis CNC device circulate along the X, Y, and Z planes. These actions allow the system to cut, drill, or shape the fabric from any direct path. For instance, it may flow horizontally, vertically, or diagonally. This flexibility way it can work on complicated parts that want specific cuts at distinctive angles.

Rotational Movements at Any Angle

In addition to moving in immediate traces, a ten-axis CNC machine also can rotate the cloth. This rotation takes place around 4 exceptional axes, often referred to as A, B, C, and every so often a second A axis. These rotations permit the system to tilt the material or rotate it absolutely, permitting it to work on curves, circles, and other complicated shapes. The rotational axes can pass the material to any angle, permitting the device to approach the part from diverse guidelines.

Simultaneous Multi-Axis Machining

One of the most spectacular features of a 10-axis CNC machine is its ability to transport in more than one guideline simultaneously. This capability lets the machine acquire compound angles. For example, it can cut or drill an element at an angle that is not perpendicular to any of the primary axes. This approach that the machine can paint on components with very complicated geometries, developing angles which might be difficult or impossible to obtain with less complicated machines.

Why Are These Angles Important?

The capability to paintings at diverse angles is essential for several reasons:

Precision and Accuracy

When manufacturing parts, mainly for industries like aerospace or clinical devices, precision is critical. A 10-axis CNC machine can acquire angles with severe accuracy, making sure that every part meets specific specifications. This degree of precision reduces errors and minimizes the need for manual changes.

Complex Geometries

Some parts have very complicated shapes that require machining from more than one angle. For example, a turbine blade or a clinical implant would possibly want cuts and curves from various guidelines. A 10-axis CNC machine can cope with those duties, growing complex components that might be hard to supply with a much less superior device.

Efficiency

By being able to paint at any angle, a 10-axis CNC system reduces the want for multiple setups or repositioning of the material. This efficiency speeds up the manufacturing process and decreases the chances of mistakes. It additionally lets in for greater constant production, which is critical for industries that require excessive volumes of the same elements.

Where to buy 10 axis CNC device?

If you’re looking to shop for a 10-axis CNC machine, Junying CNC Machining Center is an excellent place to go. They provide exceptional machines that deliver precision and efficiency for all your machining wishes. Junying is thought for its dependable merchandise and wonderful customer service, making it a pinnacle desire for experts in the production industry. Whether you need a 10-axis CNC system for complex initiatives or targeted paintings, Junying has the best answer.

FAQs About 10-Axis CNC Machines

Is a 10-axis CNC machine tough to operate?

Operating a ten-axis CNC system requires specialised training because of its complexity. However, once you discover ways to use it, the machine’s superior functions make it simpler to acquire specific and complex angles.

Are 10-axis CNC machines pricey?

Yes, 10-axis CNC machines are normally more costly than less complicated machines like three-axis or five-axis fashions. However, the funding is worth it for industries that require high precision and complicated machining capabilities.

Final Words

A 10-axis CNC system is an effective tool that can obtain angles some distance past what less difficult machines can do. With its capacity to transport in more than one guideline simultaneously, it may cope with complex geometries and specific cuts, making it a crucial device in industries like aerospace, clinical devices, and automobile production.