In today’s fast-paced world, businesses need to be able to deliver high-quality products and services quickly and efficiently. That’s where CNC machining comes in—a manufacturing process that uses computer-controlled machines to create intricate parts with accuracy and precision. But what exactly is CNC machining, and how can it benefit your business? In this blog, we will take a deep dive into the world of CNC machining services.

From understanding the different types of CNC milling and turning services to exploring the benefits of precision cutting and CNC machining, we’ve got you covered. We’ll also discuss common materials used in CNC machining, flexible pricing options for these services, and choosing the right provider for your needs. Whether you’re looking to manufacture aerospace parts or automotive components, this blog has everything you need to know about custom CNC parts.

CNC Milling Service Overview

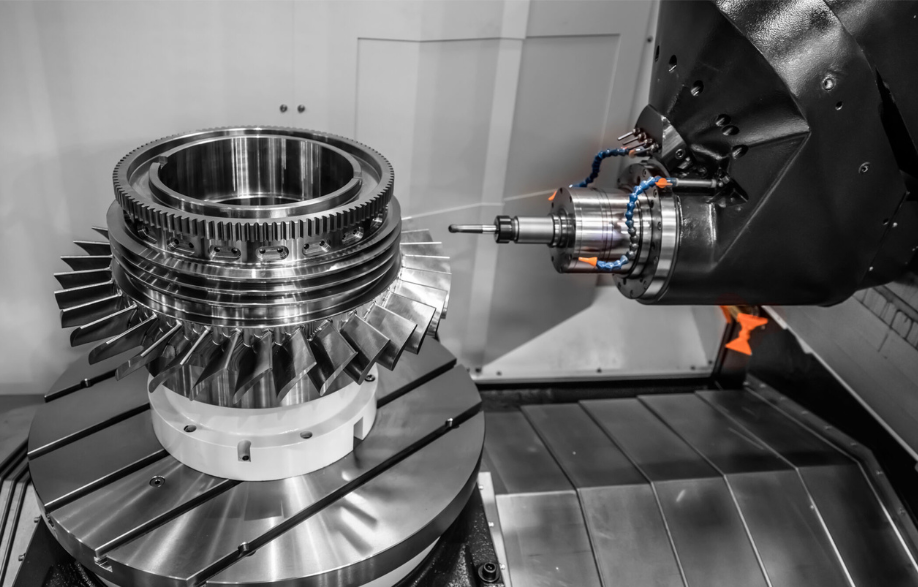

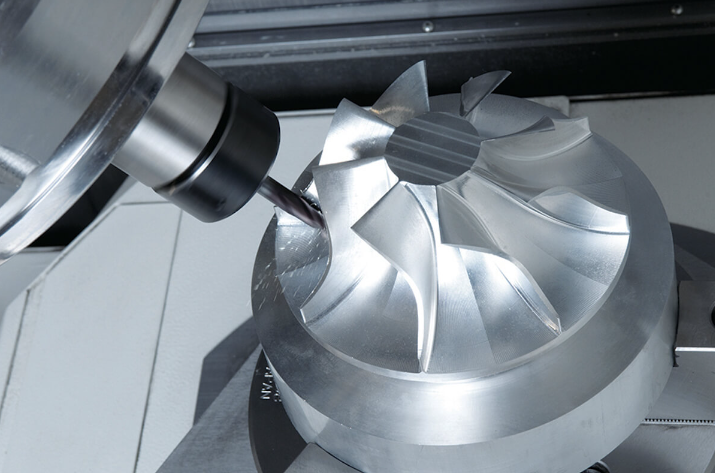

With CNC machining service, you can employ a subtractive manufacturing process that utilizes computer-controlled machines to eliminate material from the workpiece. CNC milling service allows faster production times while maintaining high-precision levels and accuracy. You can use this service to manufacture custom parts and components with complex shapes and designs using materials such as metals, plastics, or composites. By adopting CNC milling services as part of your manufacturing process, you can expect improved efficiency compared to traditional methods without compromising on quality.

CNC Milling vs. Turning Services

CNC milling and turning are two widely used techniques in the manufacturing process of custom parts and components. Turning is best suited for cylindrical parts, whereas milling allows you to create intricate designs with precision and accuracy. Milling uses rotating cutting tools to reduce material while turning rotates the workpiece against a steady cutting tool.

Depending on your requirements, you may choose either of these highly efficient services to achieve your desired results. From prototyping to production parts, CNC machining offers online solutions with shorter lead times that ensure fast delivery of machined parts in materials such as titanium, stainless steel, nickel alloys, copper, brass, PTFE, Peek, nylon, or polycarbonate.

What is Precision CNC Machining?

Precision CNC machining is a manufacturing process that utilizes computer numerical control to create highly accurate and intricate parts from materials like metal or plastic. It offers tight tolerances and complex designs, making it ideal for industries such as aerospace, automotive, and medical devices.

CNC Machining Services | Benefits of CNC Machining

If you’re considering manufacturing custom parts or prototypes, then you would do well to consider the benefits of CNC machining services. The highly precise nature of this subtractive manufacturing process ensures that parts are produced with tight tolerances and precision. In addition to being precise, CNC machines are also versatile and can produce a wide range of complex shapes and designs.

This results in greater flexibility and more design freedom when creating your project’s components. Furthermore, CNC machines are efficient and reduce the need for manual labor, which leads to considerable cost savings for businesses looking to scale up production or involve rapid prototyping in their workflow. Finally, the detailed monitoring and inspection provided by CNC machines ensure high-quality parts with minimal defects.

Common Materials Used in CNC Machining

Metals like aluminum, steel, brass, and copper are commonly utilized in CNC machining. On the other hand, plastics such as PVC, polycarbonate, and nylon prove to be versatile materials for prototyping.

In addition to these popular materials, composites like carbon fiber and fiberglass offer strength without adding weight while ceramics such as zirconia provide wear-resistant properties ideal for aerospace production parts. Woodworking materials can also be shaped by some CNC machines- offering a remarkable production process solution.

Copper CNC Machining Services

With its high conductivity and corrosion resistance, copper is a popular choice for creating intricate and precise parts using CNC machining. Widely used in electronics, plumbing, and architecture industries due to its unique material properties, machined copper parts can be shaped into a variety of complex designs and shapes. Machining techniques such as subtractive manufacturing or precision cutting are utilized to produce detailed parts with the highest accuracy possible.

Brass CNC Machining Services

CNC Brass machining services are widely known for their excellent corrosion resistance and ease of machinability making it an ideal option for producing custom parts compared to Titanium or Stainless Steel. Precise tolerances and intricate designs being met by experienced CNC machining providers who follow the right techniques of machining can result in high-quality custom-machined brass parts.

Various industries including plumbing fixtures, musical instruments, and decorative hardware manufacture use this material due to its low-cost production process. Picking a qualified CNC machining provider will guarantee top-notch quality when it comes to producing custom brass machined parts.

PTFE CNC Machining Services

CNC machining service are infusing new life into the manufacturing process; PTFE CNC machining services are no different. They are a game-changer for industries like aerospace and medical devices that require high-quality products with tight tolerances and complex geometries.

Offered by numerous service providers globally, these services use computer numerical control (CNC) machines to produce critical components made of materials such as PTFE. The material’s unique properties make it ideal for harsh environments like the food processing industry or where high-temperature resistance is crucial.

Peek CNC Machining Services

Polyether Ether Ketone or PEEK is a thermoplastic material that exhibits excellent mechanical properties and is commonly used in CNC machining processes. With resistance to high temperatures and harsh environments, PEEK finds extensive application in the aerospace and medical sectors for its ability to withstand extreme conditions.

The material’s versatility allows it to be machined into complex shapes with utmost accuracy, making it ideal for producing custom parts and prototypes.

Flexible Pricing for CNC Machining Services

CNC machining service providers have flexible pricing options that can benefit clients who want to budget their projects effectively. Custom quotes based on specific project requirements and materials used can help you save costs. Volume discounts are also commonly offered by these providers for larger orders.

If you need your project done faster than usual production times, some companies offer expedited services at an extra cost. With these options available to you, it’s important to consider both upfront costs and long-term benefits when choosing a CNC machining provider.

Conclusion

CNC machining is a game-changer in the manufacturing industry. It offers precision, speed, and accuracy that traditional methods fail to achieve. With a wide range of materials and applications available, CNC machining can cater to various industries such as aerospace, medical, automotive, and more.

To ensure you get quality parts that meet your requirements, it’s crucial to choose the right CNC machining provider. Consider factors like pricing, location, ISO certification, and online instant quotes for better decision-making. At our company, we offer flexible pricing options for all our CNC machining services with ISO certification. Contact us now to get started on your next project.