If you start a CNC machine business, it is a great idea. It is used in many industries, such as the aerospace and automotive sectors. These gadgets have two characteristics: accuracy and speed. The guidelines listed below may help you launch this machine business. Read up on the market to find out what people want most. The next step should be to create a basic business plan. After that, get some good CNC tools and learn how to use them. Put your business together and advertise your offer to reach customers. You’ll succeed if you heed this advice.

How to start a CNC machine business

Do the research and plan for the CNC machine business

This machine company requires, first, an understanding of the market. Find out more about the array of services the CNC machining sector provides. Which market—makers, hobbyists, or automakers—are you aiming for? Knowing your client’s needs will enable you to provide them with top services.

First, draft a company plan. The organization of your company is crucial. Put down in writing your objectives and the actions you want to take to meet them. Tell them what kinds of services, including drilling, turning, and milling, you provide. Together with market rates, your expenses should dictate your pricing approach. Arrange the way you will promote your company to get clients. A detailed company strategy will be your success roadmap.

Setting Up Your CNC System Business

Correctly locating your machine company is essential. Pick a workshop big enough to house your CNC supplies and equipment. Assure vendors and clients that they may easily visit the website. A prime site might be the secret to the smooth running of your business.

Register your company. The legal operation of your company requires registration. Select a name that does your services justice. Register your firm with the local government to get licenses and permissions. This stage guarantees your firm’s legal and compliant operation with local laws.

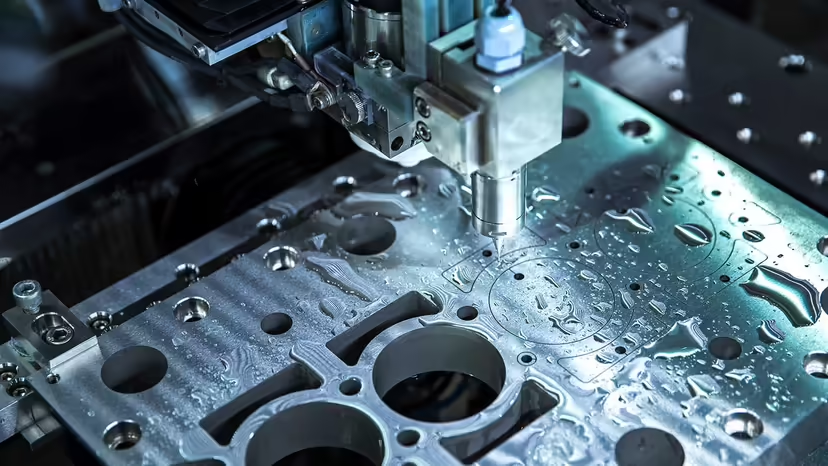

CNC machine business’s Equipment and Supplies

Spending money on machines should be done sensibly. Look into the many machine kinds to see which will suit your requirements and budget the best. Think about aspects like size, accuracy, and machine capabilities. Investing in excellent equipment will enable you to provide your clients outstanding services.

You also need the essential supplies and equipment for these machines. Get the basic materials—such as metal or plastic—and drills you’ll need for the job. A well-filled inventory guarantees that you can go right to work on projects.

Training and Skills to operate CNC machine

The operation of these machines requires a certain level of knowledge. Enroll in courses to learn machine operation and CNC programming. Practice will help you to hone your abilities. The more business you draw in with better quality work, the more competent you will be.

Hire an expert CNC operator to grow. Larger jobs may be performed, and high work standards may be maintained with the help of experts. Keeping your members current with new methods and technology calls for continuous training.

How to do Marketing and Sales for the business

You need a stunning website for your company. Build a simple yet educational website to highlight your offerings. Put up nice pictures of your work and thorough service descriptions. And give your contact details. A professionally made website may increase your internet visibility and draw clients.

The growth of your clientele depends on networking. Register with regional business associations, trade exhibitions, and industry events. Make contacts with companies that could want CNC machining services. Developing a solid rapport with customers might result in enduring alliances and steady commerce.

What are the best ways to manage your business?

The success of your firm depends on efficient financial management. Automation of your revenue and spending management is possible with accounting software. Save thorough transaction documentation, including invoices, checks, and receipts. Keeping an eye on your money allows your company to keep growing and enables you to make wise choices.

High quality and maintenance are crucial. Verify and correct your work often. Set a quality control step to ensure that each item meets your clients’ expectations.” A good job will bring in referral business and help to build a reputation.

Provide first-rate customer service. Being different from the competition might be possible with outstanding customer service. Tell your clients right away how the project is progressing and looking. Uphold regularity, follow a schedule, and take quick action to solve issues. Pleased clients are more inclined to tell others about your services.

Building a company takes time, work, and a significant financial commitment. These pointers will help you launch a successful CNC machining company.

Which is the top site online for CNC machine business?

If you’re interested in starting a CNC system business, see Junying. Junying knows a lot about this machinery. They review and use their software. The website also advises beginning a company that sells these machines. There is also plenty of information on tool selection and market research. Most importantly, Junying is an excellent resource. On Junying’s, you may get all the information required to start your business.

In the end,

Planning is essential when starting a CNC system business. You need to educate yourself about the company. And you need the inclinations of your target audience. Developing a business plan can assist you in making sure your goals are achieved. Select high-quality CNC tools to guarantee accurate and reliable operation. Quickly disseminate the word about your business. Keep up with local and technological advancements. With our help, you might create a successful business that grows.