Have you ever wondered how metal parts in your bike or car are made so precisely? Many of these parts are cut using a CNC laser cutting machine. CNC stands for Computer Numerical Control. It’s a fancy way of saying that a computer guides the machine to cut materials with extreme accuracy. Let’s explain howcnc laser cutting machine works and where to buy it!

What is CNC Laser Cutting?

CNC laser cutting uses a powerful laser to cut through materials. The laser beam is controlled by a computer, making the process very precise. This machine can cut through various materials like metal, plastic, wood, and more.

The Parts of a CNC Laser Cutting Machine

- Laser Resonator: This part generates the laser beam.

- Beam Path: The path through which the laser travels.

- Cutting Head: Where the laser focuses to cut the material.

- Table: The surface where the material to be cut is placed.

- Control System: The computer that controls the machine.

How CNC Laser Cutting Machine Work?

Designing the Cut

First, you need a design. This design is usually created on a computer using CAD software. CAD stands for Computer-Aided Design. The software helps you draw the shape you want to cut. Once the design is ready, it is converted into a code that the CNC machine can understand. This code is called G-code.

Setting Up the Machine

Next, the material to be cut is placed on the table. The CNC laser cutting machine is then set up. This involves calibrating the machine, which means adjusting it to make sure it cuts accurately. The laser’s power and speed are also set according to the material being cut.

Generating the Laser Beam

The laser resonator generates the laser beam. This beam is incredibly powerful and can reach temperatures of up to 20,000 degrees Celsius. The beam travels through the beam path and is directed to the cutting head.

Focusing the Laser

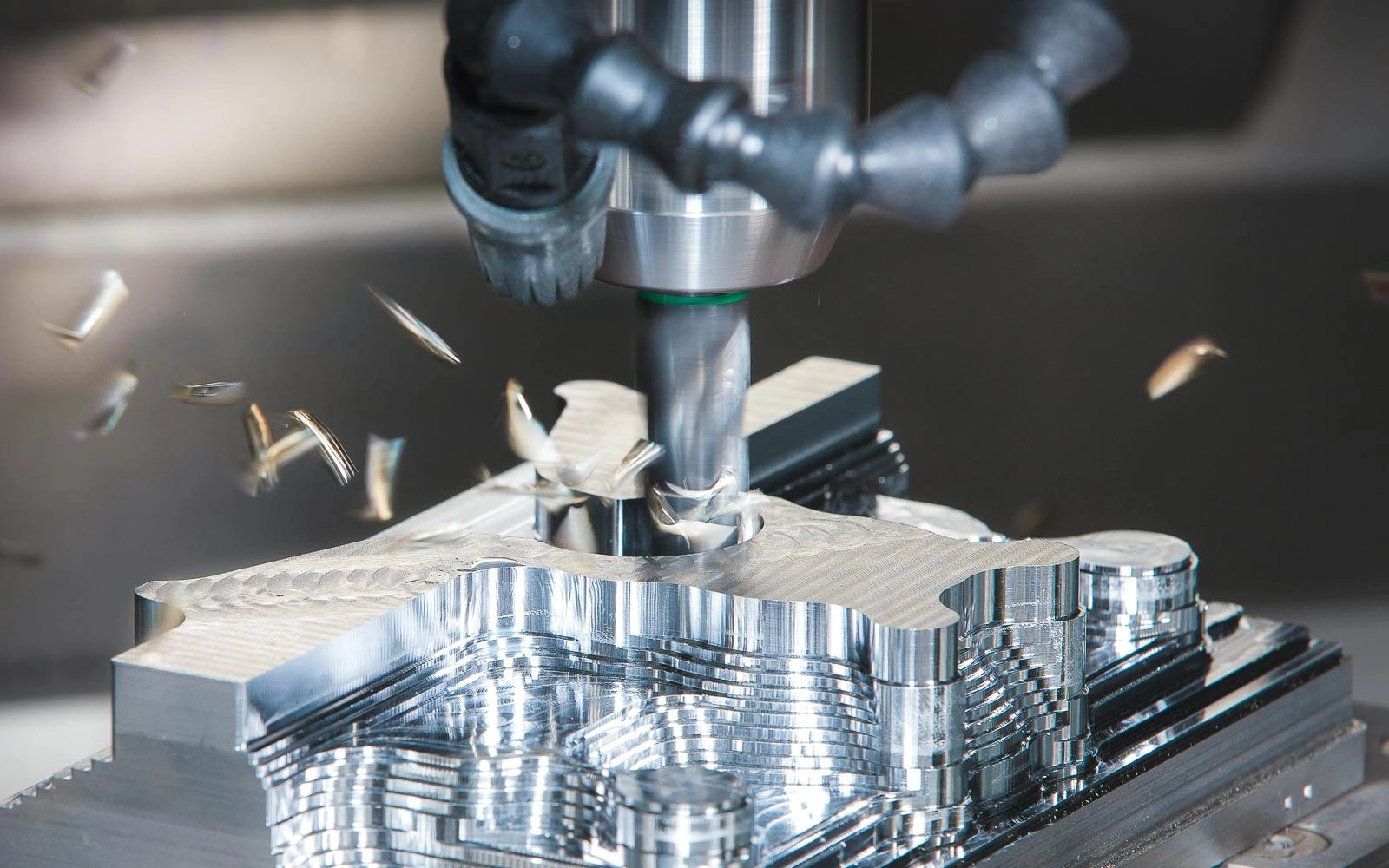

The cutting head focuses the laser beam to a very small point. This point is where the cutting happens. The focused laser beam has a high energy density, which allows it to cut through materials quickly and precisely.

Cutting the Material

The computer controls the movement of the laser cutting head. It follows the G-code to cut the material according to the design. The laser melts, burns, or vaporizes the material along the cutting path. Because the laser is so precise, it can cut very intricate designs with smooth edges.

Removing the Cut Parts

After the cutting is complete, the cut parts are removed from the table. Sometimes, a bit of cleaning or finishing is needed to remove any remaining debris or to smooth out the edges.

Types of Laser Cutting

There are three main types of laser cutting:

CO2 Laser Cutting: Uses a gas mixture to generate the laser beam. It is good for cutting, boring, and engraving.

Fiber Laser Cutting: Uses a solid-state laser. It is very efficient and is great for cutting metal.

Nd Laser Cutting: Uses a crystal to generate the laser. It is used for both cutting and engraving hard materials.

Advantages of CNC Laser Cutting

- Precision: CNC laser cutting is very precise. It can cut complex shapes with high accuracy.

- Speed: It is much faster than traditional cutting methods.

- Versatility: It can cut a wide variety of materials.

- Quality: The cuts are clean and smooth, reducing the need for additional finishing work.

- Automation: The process is automated, reducing the need for manual labor and increasing efficiency.

Applications of CNC Laser Cutting

CNC laser cutting is used in many industries:

- Automotive: For cutting car parts.

- Aerospace: For making parts for airplanes.

- Electronics: For creating small, intricate parts.

- Medical: For cutting surgical instruments.

- Jewelry: For crafting detailed designs.

Where to Buy a CNC Laser Cutting Machine?

If you are looking to buy a CNC laser cutting machine, consider Junying CNC Machining Center. They are one of the best suppliers for high-quality CNC laser cutting machines. Junying offers machines that are precise, reliable, and easy to use. They provide excellent customer support and can help you choose the right machine for your needs. With Junying, you get great value for your money. Their machines are suitable for various materials and industries. Visit their website to explore their range and make an informed purchase.

Safety Measures

Working with CNC laser cutting machines can be dangerous. Here are some safety measures to follow:

- Wear Safety Gear: Always wear safety glasses and protective clothing.

- Proper Ventilation: Ensure the area is well-ventilated to avoid inhaling fumes.

- Training: Only trained personnel should operate the machine.

- Regular Maintenance: Keep the machine well-maintained to prevent accidents.

- Emergency Stops: Know how to use emergency stop buttons in case something goes wrong.

Final Words

CNC laser cutting machines are unimaginable devices. They consolidate the force of lasers with the accuracy of computers to cut materials precisely and rapidly. From vehicles to adornments, these machines assist with making large numbers of the things we use consistently. By understanding how they work, we can see the value in the innovation behind the items we see and use. Continuously recollect, security first while working with such strong machines!