CNC milling services are awesome for when you need to shape metal or plastic into precise parts. CNC stands for “Computer Numerical Control,” which means a computer tells the milling machine exactly what to do. Imagine a robot that carves out shapes from big blocks of material. That’s kind of what a CNC milling machine does.

Here’s how it works: You start with a digital design of the part you want to make. Then, you feed this design into the CNC machine. The machine has these super-sharp cutters that move around in all directions. As the block of material sits on the machine’s table, the cutters whizz and whirl over it. They slice away tiny bits of the material to match the design you made.

It’s like a sculptor chipping away at stone, but super precise and controlled by a computer. You can make all sorts of complex parts with CNC milling. It’s perfect for making prototypes, machine components, or even detailed works of art. The best part is that it’s all automatic, so you get identical parts every single time. It’s quick, precise, and can really handle tough jobs—pretty neat, right?

What is the CNC milling process?

CNC milling is like a high-tech way of sculpting but with metals and plastics. Let us analyze the procedure into basic steps:

Step 1: Design the Part

First off, someone dreams up a part or product they need. Using computer-aided design (CAD) software, they map out the exact dimensions and shape of this part. It’s like drawing on a computer but with super precise measurements.

Step 2: Convert to CNC Language

Next, we need to translate that design into something the CNC machine understands. Software for computer-aided manufacturing (CAM) can help with that. It turns the design into a list of coordinates and commands. This language is called G-code, and it tells the machine exactly how to move to make the part.

Step 3: Set Up the Machine

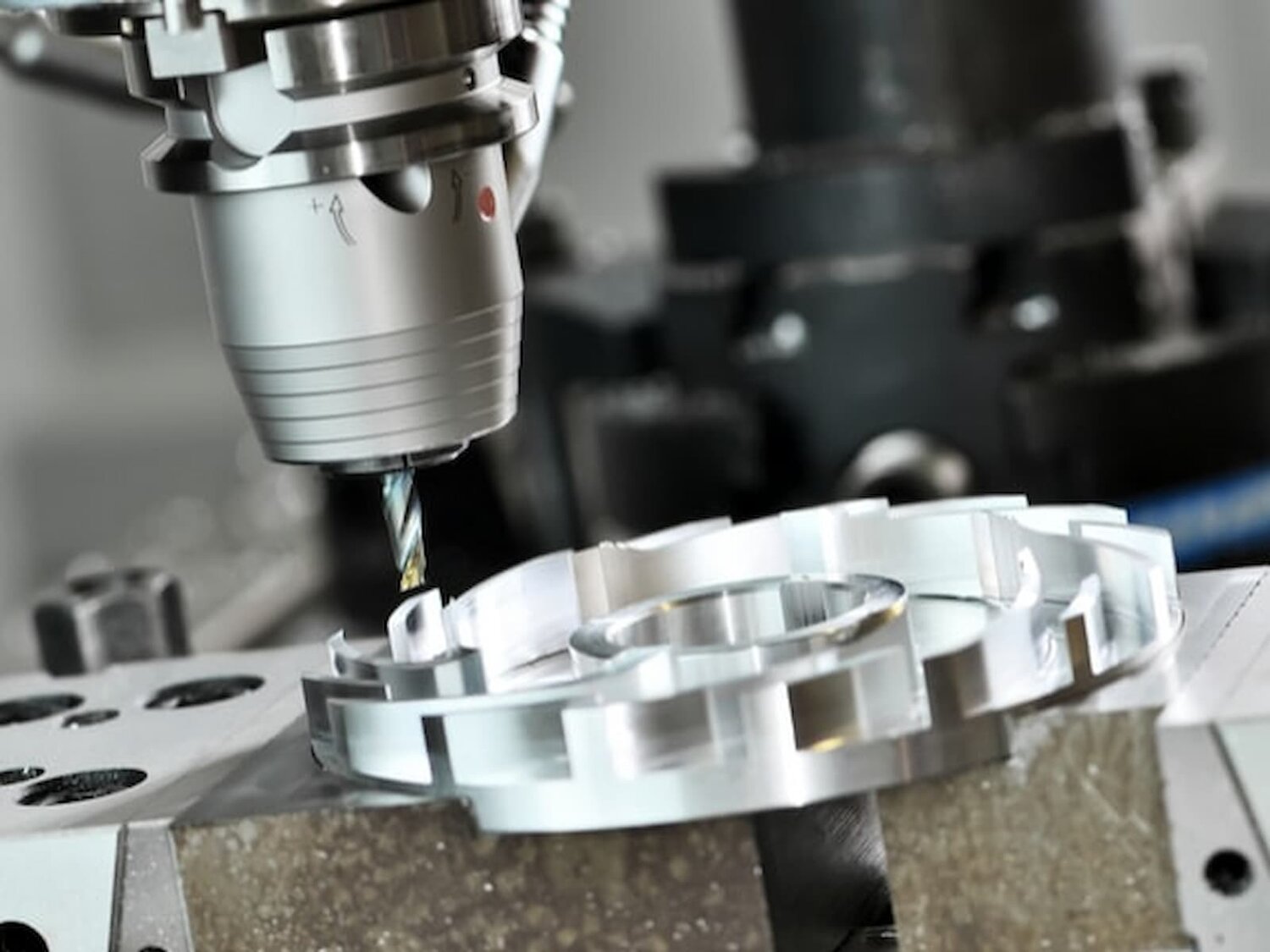

Before we start cutting, we have to get the CNC milling machine ready. We pick the right tools, like drills or cutters, and attach them to the machine. Then we secure the block of material (metal, plastic, etc.) onto the machine table. We make sure it’s super tight and won’t move around.

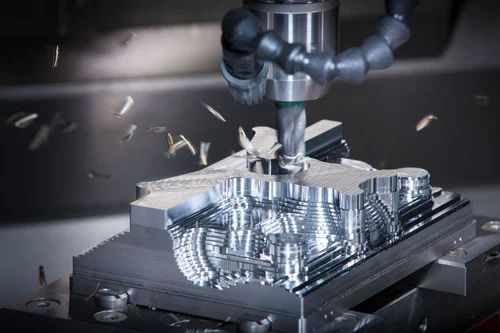

Step 4: Milling

Now the fun begins! We turn on the machine, and it starts to move the cutters to the material. The machine follows the G-code instructions, cutting away pieces of the material. It moves up and down, side to side, carving out the shape programmed into it.

Step 5: Monitoring

While the machine is doing its thing, we keep an eye on it. We make sure everything is going smoothly, the cutters are sharp, and the material isn’t shifting. If something isn’t right, we pause the machine and fix it.

Step 6: Cool Down

The milling can get hot because of all the cutting. So, we use coolants or compressed air to keep the temperature down. This helps to avoid any warping or damage to the part.

Step 7: Final Checks

After the machine has done its job, we take out the part and check it over. We compare it to the original design to make sure all the sizes and shapes are just right.

Step 8: Finishing Touches

Sometimes, the part needs a little extra work after milling. We might polish it, paint it, or do other finishing processes to make it look great and work well.

CNC milling turns a digital blueprint into a real-life part. It’s all about precise movements, careful planning, and a bit of computer magic. This process can create parts for cars, planes, gadgets, and so much more. It’s a crucial step in making the complex stuff we use every day.

3 Common CNC Milling Operations

CNC milling can do a lot of cool things! Let’s talk about three common operations that CNC milling machines are really good at:

1. Face Milling

Think of face milling as giving the material a smooth shave. The machine uses a face milling cutter to make the surface flat or smooth. It moves over the material’s surface, cutting off thin layers. This is great for getting a flat finish and prepping the surface for more detailed work. You end up with a part that looks neat and is pleasant to touch.

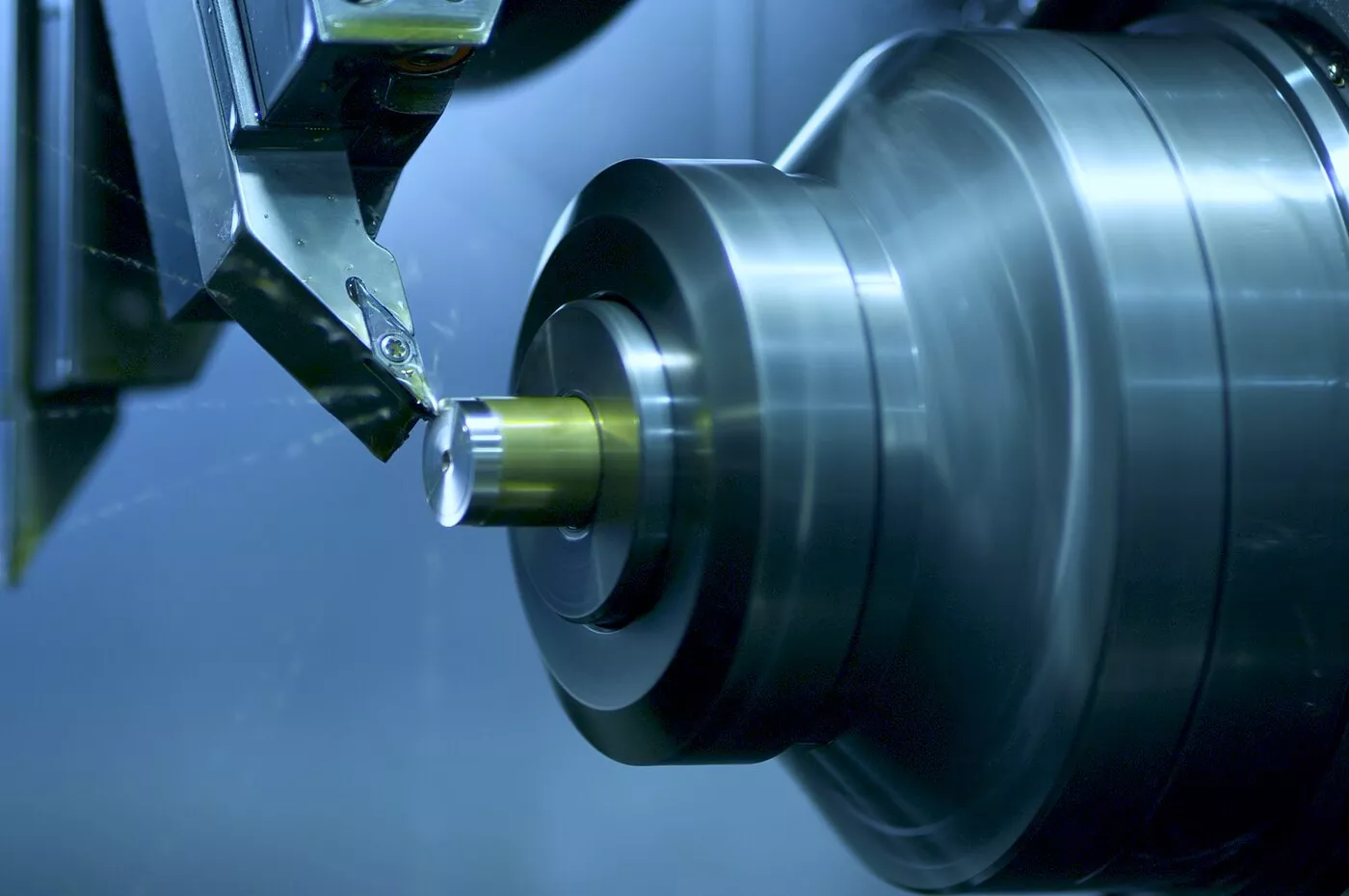

2. Plain Milling

Plain milling is all about making horizontal cuts. It’s also called slab milling. The cutter rolls over the material, slicing off parts along the way. It’s perfect for cutting broad, flat areas. Plain milling helps a lot when we need to cut the sides of a piece or make it thinner.

3. Angular Milling

When you need an angle on your part, angular milling is the way to go. The machine’s cutter tilts to carve out angles. It’s like tilting your head to get a better look at something. This method helps create slopes and grooves in the part. Angular milling is super useful for complex shapes and precise engineering work.

Why Choose Us for CNC mailing services?

When you’re looking for top-notch CNC milling services, you want a team you can trust. That’s where we come in! Here’s why you should choose us to bring your designs to life:

Expert Team: We’ve got a crew of passionate pros who know CNC milling inside and out. They love what they do, and it shows in the quality of their work. They’ll listen to what you need and make sure everything goes just right.

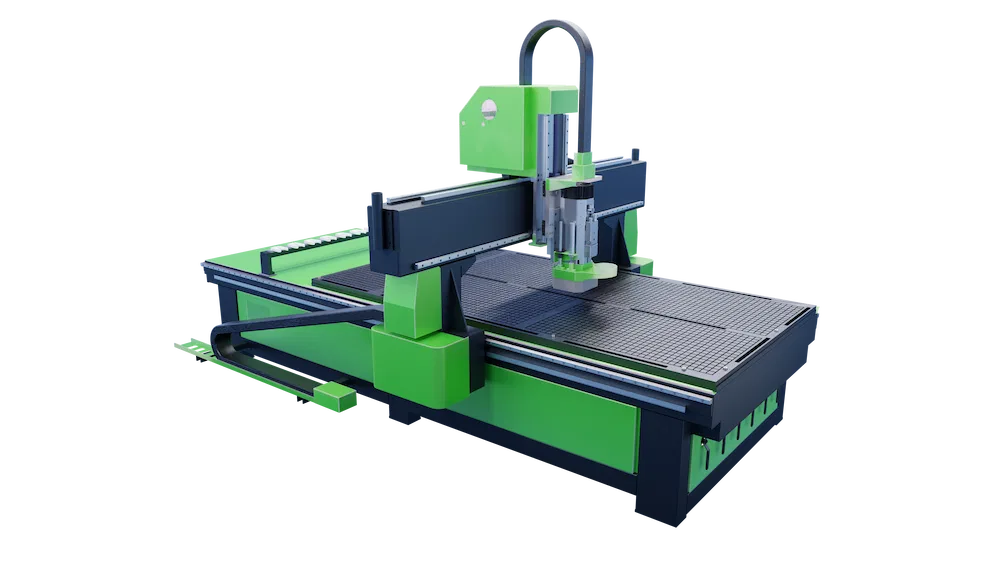

State-of-the-Art Equipment: Our workshop boasts the latest and greatest CNC machines. They can handle all sorts of jobs, big or small, simple or complex. This means we can offer you precise parts, every single time.

Attention to Detail: We’re all about the little things. Our experts double-check every part, making sure everything measures up to your specifications. We’re not happy unless it’s perfect!

Quick Turnaround: Need it fast? We’ve got you covered. Our processes are optimized to make sure you get your parts as soon as possible without cutting corners on quality.

Flexibility and Customization: Your project is unique, and we get that. We can adapt to a wide range of materials and designs. Just tell us what you need, and we’ll make it happen.

Competitive Pricing: We offer fair prices without compromising on quality. You get the best bang for your buck, with clear costs upfront and no hidden fees.

Outstanding Customer Service: We’re here for you every step of the way. Got questions? Need updates? We’re just a call or email away, ready to help.

Strong Track Record: Our portfolio is packed with successful projects. Clients come back to us because we consistently deliver. Check out our testimonials—they speak for themselves!

Sustainable Practices: We believe in looking after our planet. We work smart to reduce waste and recycle materials whenever we can. Choosing us is a choice for a greener future.

After-Sales Support: Once you receive your parts, our service doesn’t stop there. We’re here to answer any follow-up questions and assist with any further needs.

When it comes down to it, we’re not just a CNC milling service provider; we’re your partner in making things that matter. We’re committed to bringing your ideas to life with a touch of excellence, efficiency, and care that you won’t find just anywhere. So why wait?