CNC milling is the backbone of modern manufacturing, and it’s critical to understand its capabilities and limitations if you want to succeed in the industry. In this post, we will explore what CNC milling is, its process overview, the equipment, and components used, and how it works. We’ll also delve into alternatives to CNC milling and how it’s used in aerospace.

Additionally, we will highlight the benefits that come with using CNC milling machines, including their precision and accuracy. Lastly, we will cover vertical milling machines and their importance in the manufacturing industry. By the end of this blog post, you’ll have a comprehensive understanding of CNC milling and its role in modern-day manufacturing processes. What is CNC Milling? Everything you need to know about CNC milling is in this comprehensive guide. Read on to know everything about cutting technology and its uses.

What is CNC Milling?

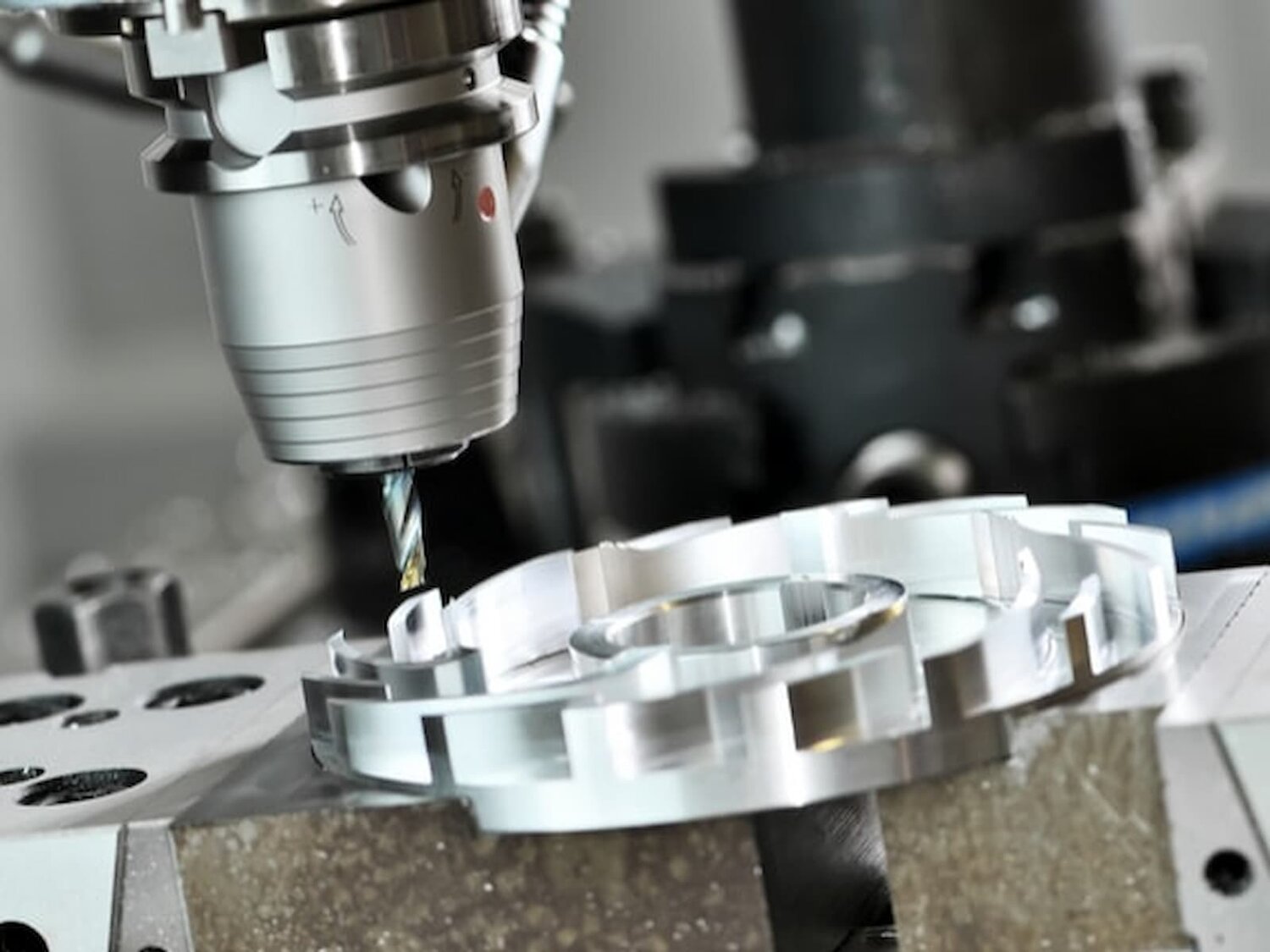

CNC milling involves using computer-controlled machines to precisely remove material from a workpiece, utilizing rotating cutting tools to create intricate designs. It is widely used in the automotive, aerospace, and medical manufacturing industries due to its accuracy and precision in producing parts and components.

CNC Milling Process Overview

Computer numerical control (CNC) milling is a subtractive machining process that carves out complex shapes and designs from various materials. To achieve precision and accuracy, different cutting tools like end mills, drills, and routers are used. A CNC milling machine operates through programming with CAD/CAM software to execute the design on the stationary workpiece. In aerospace, automotive, and medical devices manufacturing CNC milling machines are widely used due to their versatility and reliability.

CNC Milling Equipment and Components

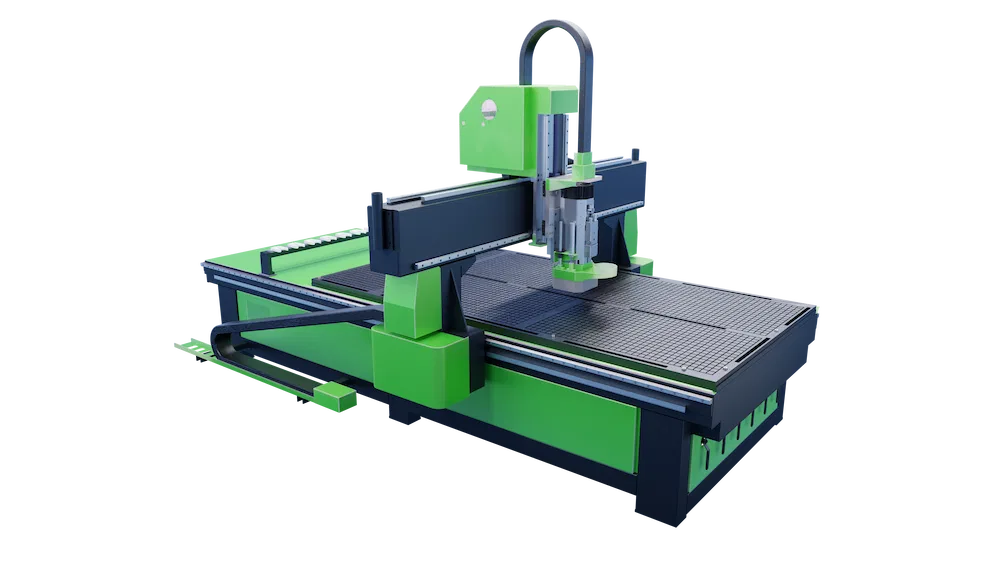

CNC milling machines utilize computer-controlled tools to remove material from a stationary workpiece accurately. These complex machines consist of different components, including spindles that rotate to shape the material being milled. The axes and numerical controls allow for precision cuts, while coolant systems and safety enclosures protect operators from hazards.

Additionally, tool changers provide increased efficiency in the production of custom-designed parts. A wide range of materials such as stainless steel, ceramics, and plastics can be cut using CNC milling technology.

What are CNC Milling Machine Components?

CNC milling machines have various components, including the spindle that rotates the cutting tool, tool holder for holding it in place, and worktable to secure the workpiece. Other vital parts include the control panel, coolant system, and motor. These components work together to provide accurate and efficient machining.

Alternatives to CNC Milling

Apart from CNC milling, there are various alternative methods available to manufacture products. Traditional manual milling requires a skilled operator to control the machine manually. In contrast, 3D printing creates products by building up layers instead of removing material. Laser cutting is also an effective way of creating precise shapes using high-powered lasers.

Waterjet cutting uses high-pressure water and abrasive material for precision cutting. These methods offer a wide range of options for manufacturing complex parts in different materials without relying on CNC milling alone.

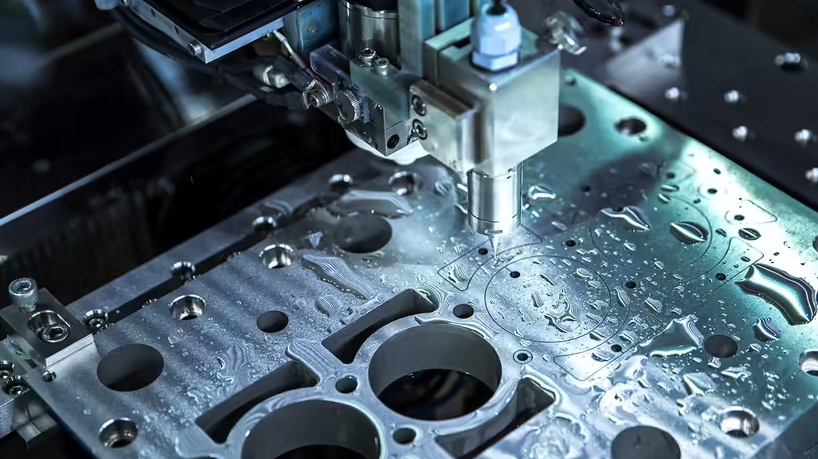

CNC Milling for Aerospace

CNC milling is widely used in the aerospace industry due to its precision, efficiency, and cost-saving benefits over traditional manufacturing processes. With advanced technology, CNC milling machines can produce complex shapes and parts with high accuracy. The industry heavily relies on this machining process for the production of aircraft components. CNC milling service providers use computer-aided design (CAD) software to create a model, which is turned into a machining program using computer-aided manufacturing (CAM) software.

The programs control the machine’s axes so that the cutter can move along the workpiece’s surface in three or more axes for creating custom-designed parts. CNC milling machines consist of several components such as a spindle, tool holder, worktable, control panel, coolant system, and motor. They can work with a wide variety of materials ranging from plastics to ceramics or even stainless steel while producing grooves, contours, angular milling, and flat surfaces by a plain milling process or face & form milling operations.

Benefits of CNC Milling

Computer numerical control (CNC) milling is an advanced machining process that involves using cutting tools to shape materials ranging from stainless steel to ceramics. A CNC milling machine operates in three axes, enabling it to produce custom-designed parts with precision and efficiency. By utilizing computerized controls and sophisticated cam software, CNC milling can create complex components with ease.

With its versatility and ability to produce different types of cuts like flat surfaces or angular milling while reducing production time and costs, CNC milling has become vital in various industries like aerospace and medical devices.

Vertical Milling Machines

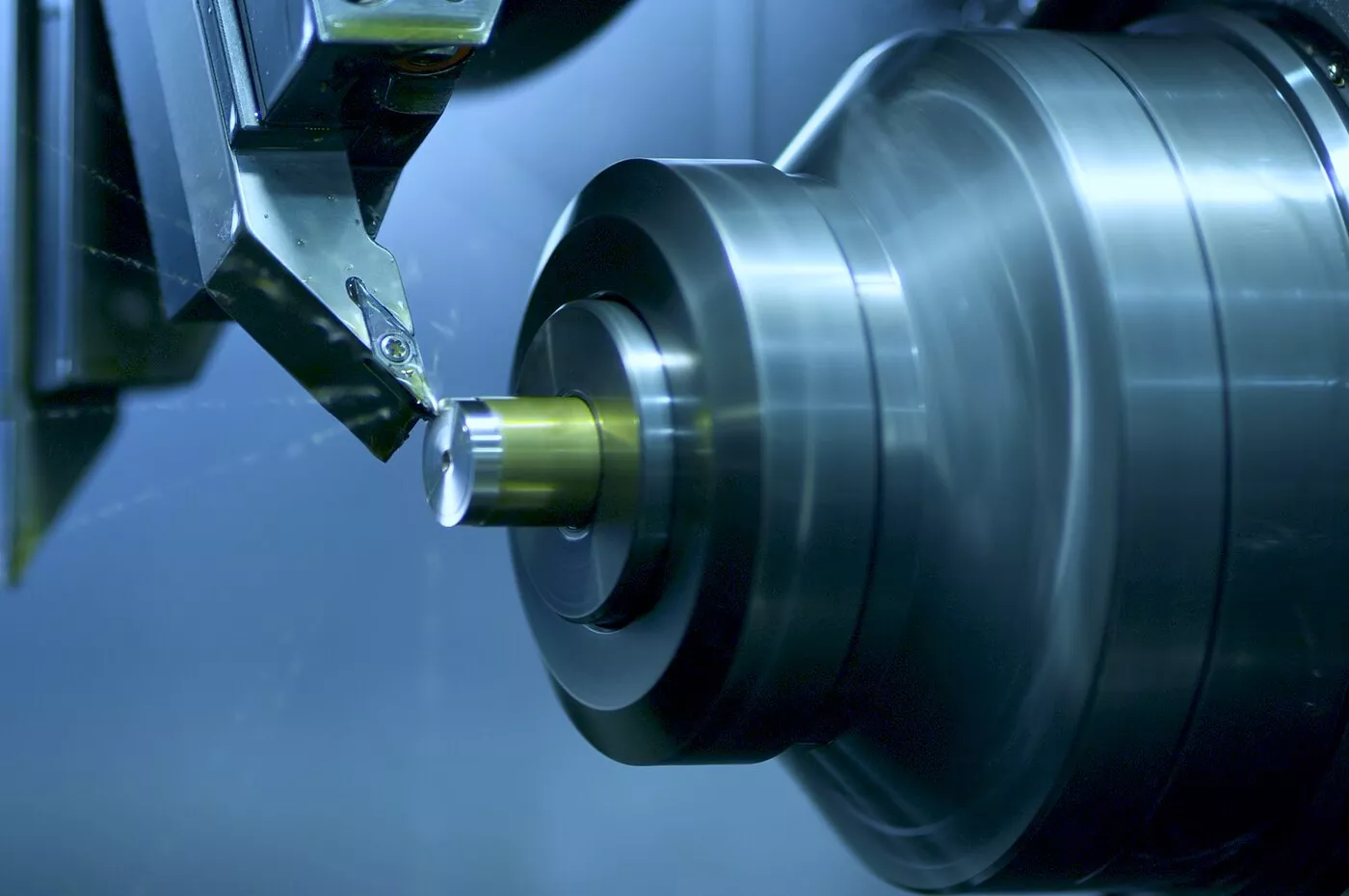

Precision is key in CNC machining, and vertical milling machines offer just that. By using a spindle perpendicular to the stationary workpiece, these machines provide greater control over the cutting tool. From plain milling to form milling to face milling, vertical milling machines can shape desired geometries with ease.

With advanced computerized controls and a wide range of secondary key terms like axes, robotics, and cutting tools at their disposal, machinists can create complex parts out of materials ranging from ceramics to stainless steel.

How Does CNC Milling Work?

CNC milling involves using CAD software to create a 3D model, which is then uploaded to the machine. The machine uses precision cutting tools and G-code instructions to remove material from a block or sheet of material. This process can produce highly accurate and intricate parts using various materials.

Conclusion

CNC milling is a process that is used to create complex shapes and designs with high precision. It involves the use of computer-controlled machines that are capable of cutting and shaping various materials with ease. The components and equipment used in CNC milling vary depending on the specific application, but they all work together to create highly accurate parts and components.

If you are interested in learning more about CNC milling, its benefits, and how it works, read our comprehensive guide on everything you need to know about CNC milling. Whether you are involved in aerospace or any other industry that requires precision machining, understanding CNC milling can help you achieve your goals.