Polishing aluminum by hand is not just about making it look shiny; it’s an art that combines skill and patience to breathe new life into metal. This process holds great importance, especially in preserving the beauty and longevity of aluminum items. Whether it’s a cherished family heirloom, a prized component of a classic car, or everyday kitchenware, hand polishing ensures that these items not only look their best but also resist corrosion over time. It’s a fulfilling, hands-on approach that allows for meticulous attention to detail, ensuring every inch of the aluminum surface receives the care it deserves.

Polish aluminium: what it is?

Polishing aluminum is a process that enhances its appearance and increases its resistance to corrosion. When you polish aluminum, you use abrasives to smooth its surface, giving it a shiny, mirror-like finish. This process removes oxidation and surface imperfections, making the aluminum look new and vibrant. It’s a popular method in automotive and household applications, where aesthetics are key. By polishing aluminum, you not only improve its look but also extend its lifespan, as a smoother surface is less prone to corrosion.

Aluminum Hand Polishing Vs. Machine Polishing

When it comes to achieving that mirror-like finish, you have two main options: hand polishing and machine polishing. Every technique has certain benefits and things to keep in mind.

Understanding Hand Polishing

Hand polishing aluminum is a traditional method, requiring simple tools like a soft cloth and polishing compound. It’s a process where you manually rub the surface to create a shine. This method allows for meticulous attention to detail. You can easily reach nooks and crannies, ensuring an even and thorough polish. Hand polishing is often more affordable as it doesn’t require expensive equipment.

Advantages of Hand Polishing

Precision and Control: You have complete control over the pressure and area, reducing the risk of damaging the aluminum.

Accessibility: It’s easier to polish intricate designs and hard-to-reach areas by hand.

Cost-Effective: Hand polishing requires minimal investment in tools and materials.

Limitations of Hand Polishing

Time-Consuming: It can take a lot of time and effort, especially for larger items.

Physical Effort: It’s physically demanding and can be tiring, especially on larger projects.

Inconsistency: Achieving a uniformly polished surface can be challenging, especially for beginners.

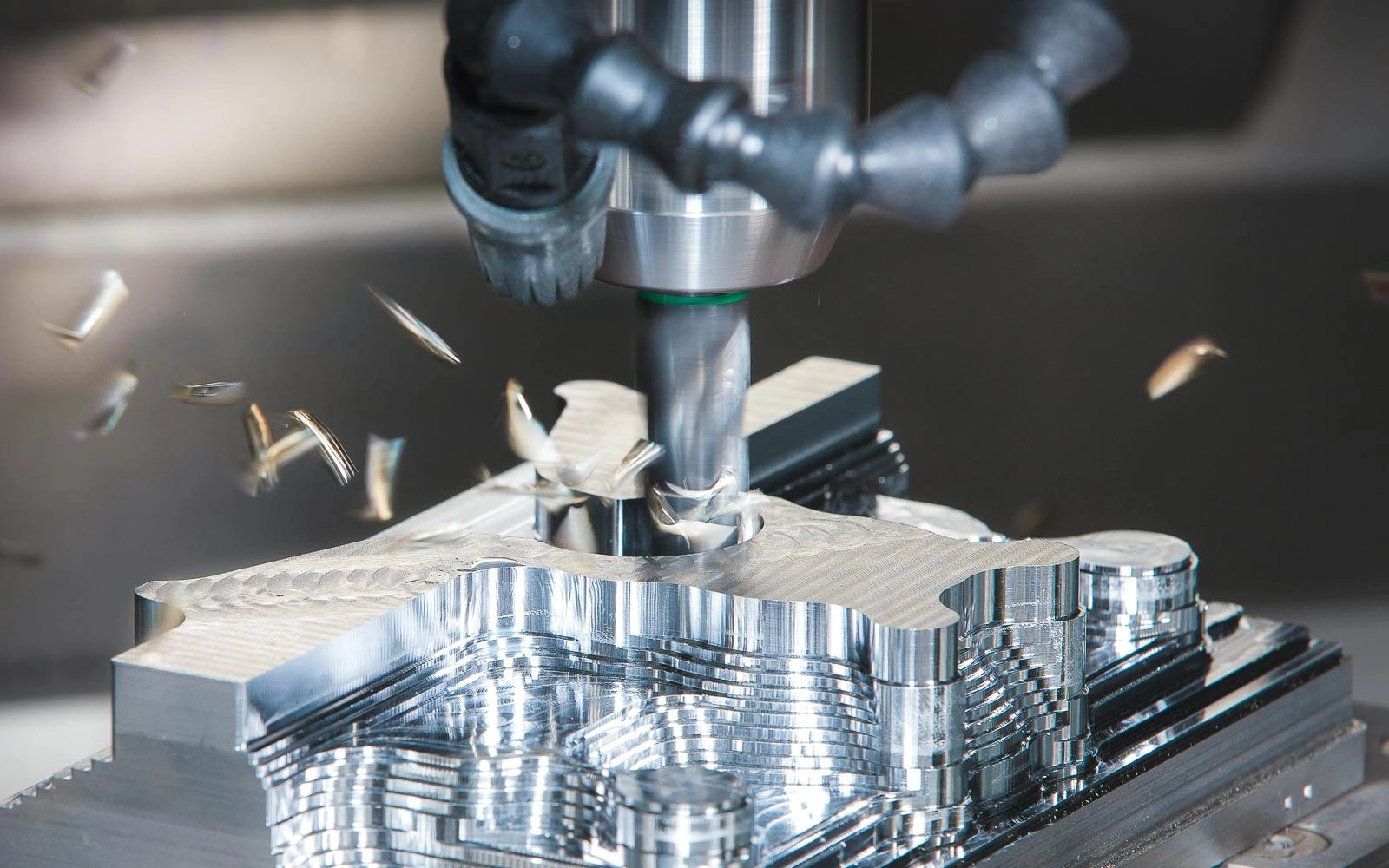

Exploring Machine Polishing

Machine polishing uses a powered tool, like a rotary or dual-action polisher, to buff the aluminum surface. This method is much faster and less physically demanding than hand polishing. Machines provide a consistent level of abrasion, which can result in a more uniform finish. It’s particularly effective for large surfaces or when you need to polish regularly.

Advantages of Machine Polishing

Efficiency: It saves a significant amount of time and effort, especially on larger surfaces.

Consistent Results: Machines provide a uniform application, which can lead to a more even polish.

Less Physical Strain: The machine does the hard work, reducing the physical effort required.

Limitations of Machine Polishing

Cost: Initial investment in a good quality polisher and accessories can be high.

Learning Curve: It takes time and practice to master the technique without damaging the surface.

Accessibility: It might be challenging to reach tight or intricate areas with a machine.

Choosing the Right Method

Deciding whether to hand polish or machine polish aluminum depends on several factors. Consider the size of the item, the level of detail, your budget, and how often you plan to polish. Hand polishing might be more suitable for smaller, intricate items or if you’re on a tight budget. Machine polishing, on the other hand, is ideal for larger surfaces or when you need a high-quality finish quickly.

How to polish aluminium by hand?

Polishing aluminum by hand is a rewarding process that can bring out the best in your aluminum items, whether they’re parts of a vehicle, kitchenware, or decorative objects. Here’s a step-by-step guide.

Step 1: Gather Your Materials

First things first, you need to gather all the necessary materials. For hand-polishing aluminum, you’ll need:

- Sandpaper (various grits from 400 to 2000)

- Polishing compound

- Clean, soft cloths

- Protective gloves

- Safety goggles

- Water (for wet sanding)

- A bucket or container (for water)

- A soft brush (optional, for cleaning)

Step 2: Clean the Aluminum Surface

Before you start polishing, it’s important to clean the aluminum surface. Remove any dirt, grease, or debris. Use a soft brush and a mild detergent if necessary. Once you’ve cleaned the surface, dry it thoroughly. A clean surface ensures that your polishing efforts are effective.

Step 3: Sanding the Aluminum

Sanding is crucial for removing any oxidation and smoothing out the surface. Start with a lower grit sandpaper, like 400 grit. Sand the aluminum in a circular motion. If you’re wet sanding, dip the sandpaper in water regularly to keep the surface lubricated. This helps to avoid scratches.

Step 4: Progress to Finer Grits

Once you’ve sanded the entire surface with 400 grit, move to a higher grit, like 600. Repeat the sanding process. Gradually work your way up to the finest grit you have, like 2000. Each time, the aluminum will look smoother. Remember to clean the surface between each sanding step to remove any aluminum dust.

Step 5: Applying the Polishing Compound

After sanding, it’s time for the polishing compound. Apply a small amount of the compound to a clean, soft cloth. Rub it onto the aluminum in a circular motion. To achieve uniform covering, work in tiny parts. The compound will fill any tiny scratches and begin to bring out the shine.

Step 6: Buffing

Once you’ve applied the polishing compound to the entire surface, buff it off with a clean, dry cloth. Put some elbow grease and circular movements to use. This step is where you’ll start to see the aluminum shine. Make sure you buff off all the compound residue.

Step 7: Inspect and Repeat if Necessary

After buffing, inspect the aluminum. If it’s not as shiny as you’d like, repeat the polishing and buffing steps. Sometimes, it takes a few applications to get the desired level of shine.

Step 8: Final Buffing

For the final touch, give the aluminum a good buff with a fresh, clean cloth. This final buffing step removes any remaining traces of the polishing compound and enhances the shine.

Step 9: Maintenance

To keep your hand-polished aluminum looking great, regular maintenance is key. Clean the aluminum regularly and apply a protective coating if desired. This will help maintain the shine and protect the surface from oxidation.

Hand polishing aluminum might seem like a lot of work, but the results are worth it. You’ll end up with a beautifully shiny surface that looks almost new.

FAQs

Can I polish any aluminum surface by hand?

Yes, you can polish most aluminum surfaces by hand, but be careful with aluminum that has a special coating or anodizing, as polishing might damage it.

How often should I polish aluminum?

It depends on the item’s use and exposure. Outdoor items or frequently used items may need more regular polishing.

Is it necessary to sand before polishing?

Sanding is essential for removing oxidation and preparing the surface for polishing, especially if the aluminum is heavily tarnished or scratched.

Can I use a household item as a polishing compound?

While some household items can provide a temporary shine, it’s best to use a professional polishing compound for long-lasting and effective results.

How do I prevent aluminum from tarnishing after polishing?

Regular cleaning and occasionally applying a protective coating can help prevent tarnishing and maintain the shine.